Custom Sheet Metal Fabrication Services

High-Precision Metal Parts with Stamping, Bending & Laser Cutting

- Certifications ISO 9001:2015 | IATF 16949

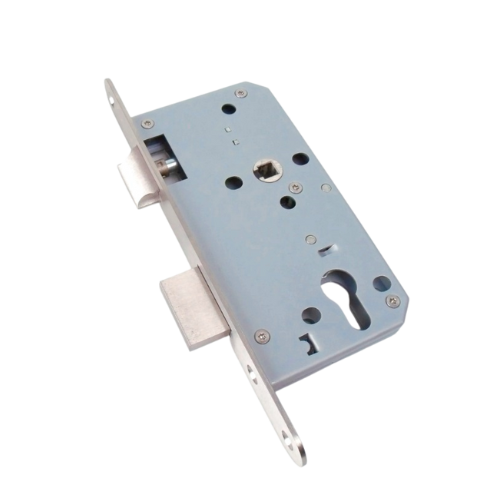

What is Sheet Metal Fabrication?

Sheet metal fabrication is a manufacturing process used to create parts and structures from thin metal sheets. It involves cutting, forming, and assembling metal materials into functional products.

Key advantages

Sheet metal fabrication offers design flexibility, cost efficiency, and scalability, making it a preferred choice for precision metal parts across industries.

Our Metal Manufacturing Capabilities

Our end-to-end approach ensures every part is fully fabricated, assembled, and finished to meet your exact specifications.

Stamping & Punching

We use 315-ton hydraulic presses and precision tooling to produce complex stamped parts and clean cutouts for both prototypes and high-volume production.

Forming & Bending

Laser Cutting

Assembly Services

Sheet Metal Material Options

Looking for something not listed?

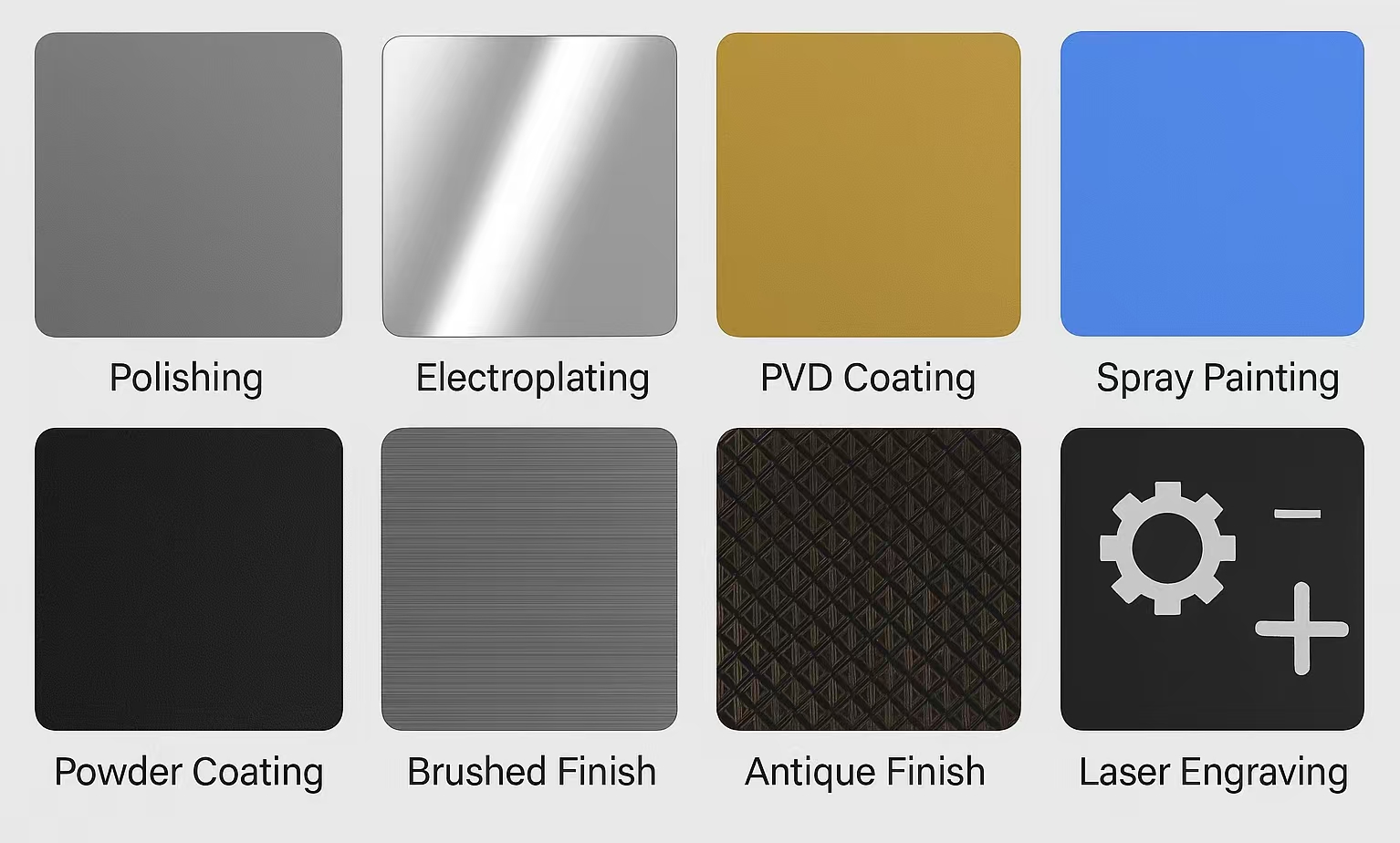

Sheet Metal Materials & Finishes

We provide diverse finishing solutions that combine aesthetics, functionality, and durability to meet the needs of various industries.

Ready to elevate your sheet metal fabrication with precision engineering and flawless finishes?

Applications

Sheet metal fabrication parts are used in a wide variety of high-performance applications:

- Automotive

- Industrial Equipment

- Consumer Electronics

- Energy & Renewable Solutions

- Construction & Architecture

Looking for a trusted partner for precision sheet metal fabrication and assembly?

Why Choose Us

20+ years of manufacturing experience

Advanced machines & strict quality control

ISO 9001 & IATF 16949

Design to finished product

Compliant with RoHS & REACH

Dedicated project tracking and global delivery

Ready to work with a reliable sheet metal fabrication partner?

FAQ – Frequently Asked Questions

Q: What products can be made with sheet metal fabrication?

A: Enclosures, brackets, panels, frames, and complex assemblies for automotive, electronics, and construction industries.

Q: Which metals are best for sheet metal fabrication?

A: Aluminum, stainless steel, carbon steel, and galvanized steel—chosen for strength, weight, and corrosion resistance.

Q: How precise is sheet metal fabrication?

A: We achieve tolerances down to ±0.1 mm for forming and even tighter for secondary machining.

Q: Do you support both small and large production runs?

A: Yes, from rapid prototyping and low volumes to full-scale manufacturing.

Q: Do you support both small and large production runs?

A: Absolutely. Our engineers optimize designs for cost-effective, high-quality production.

Q: How fast can you deliver sheet metal parts?

A: Prototypes in as little as 3–7 business days; production lead times vary by complexity.

Recent Blog Posts

需要添加几篇文章这里再引用