Press Tools for Sheet Metal

Expert tooling solutions to accelerate your metal forming projects.

- Certifications ISO 9001:2015 | IATF 16949

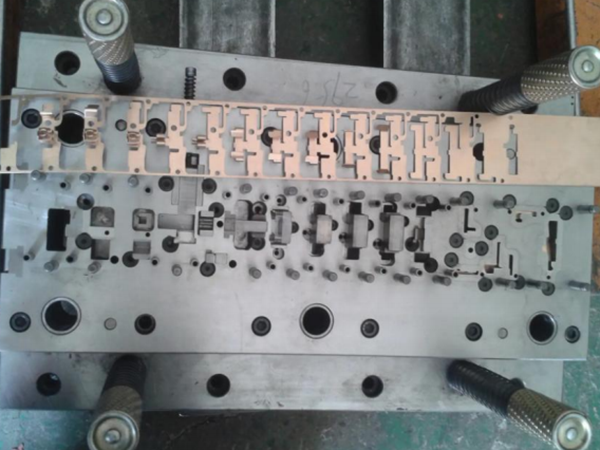

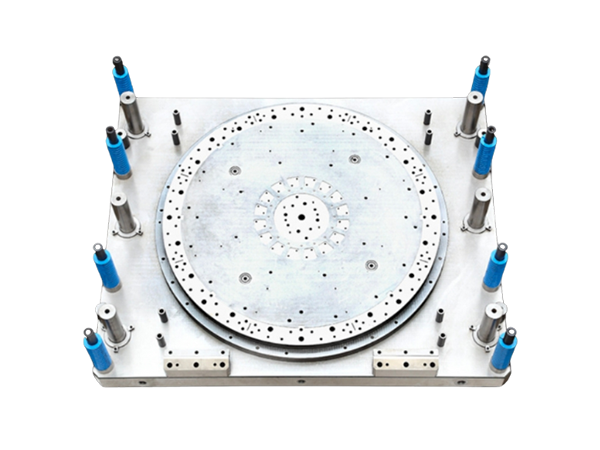

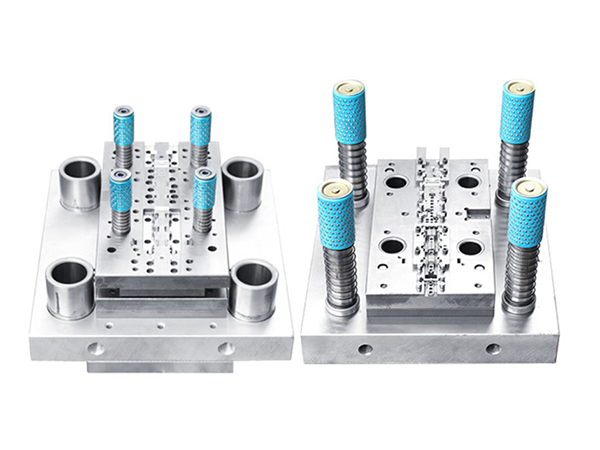

1.What is a Stamping Die?

A stamping die is a precision-engineered tool used in sheet metal forming. It enables cutting, bending, drawing, or shaping metal sheets into complex components with high repeatability and tight tolerances.

Our stamping dies are built to deliver consistent performance, long service life, and exceptional accuracy for high-volume production.

Your stamping success starts with the right die.

Our Capabilities

- Advanced solutions for progressive, compound, and deep drawing dies

- Expertise in complex geometries and tight tolerances

- 20+ years of stamping die design and manufacturing experience

- DFM (Design for Manufacturability) analysis for cost-effective, high-quality results

- Dimensional accuracy up to ±0.01 mm

- High-speed stamping die production for automotive and industrial sectors

- Serving Automotive, Industrial, Electronics,Appliance and New Energy sectors

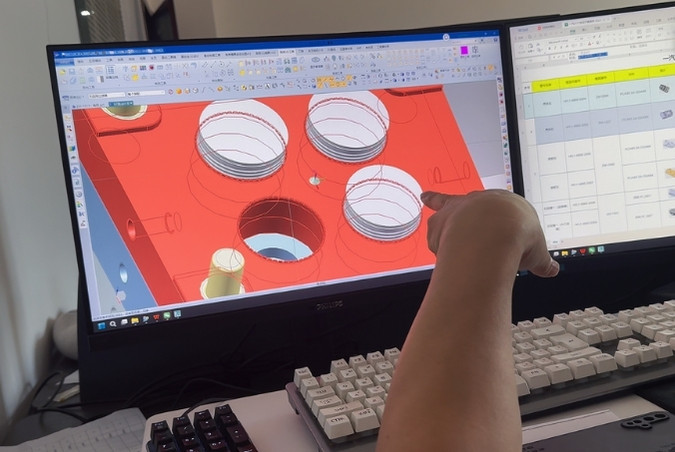

- CAD/CAM/CAE systems for optimized design and simulation

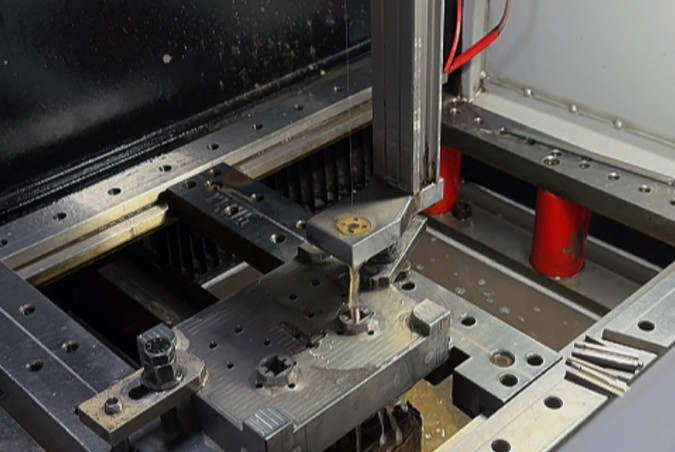

- In-house CNC machining and grinding for precision components

- Dedicated assembly, fitting, and maintenance areas

- ISO 9001:2015 certified quality system

- Comprehensive inspections with CMM and die tryouts

- Strict process control for consistent quality and long die life

Discover how our capabilities can benefit your next project

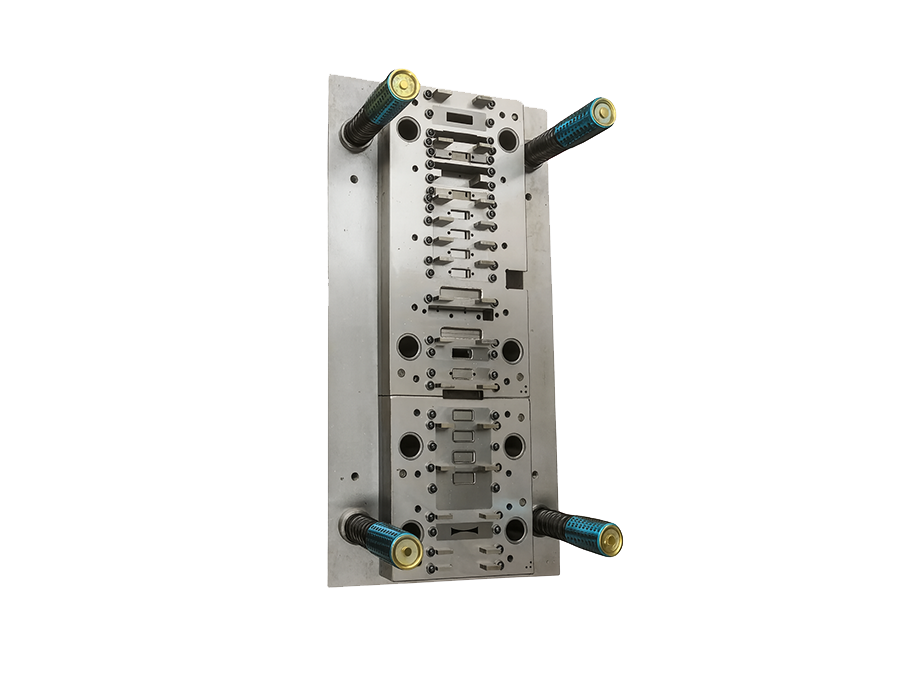

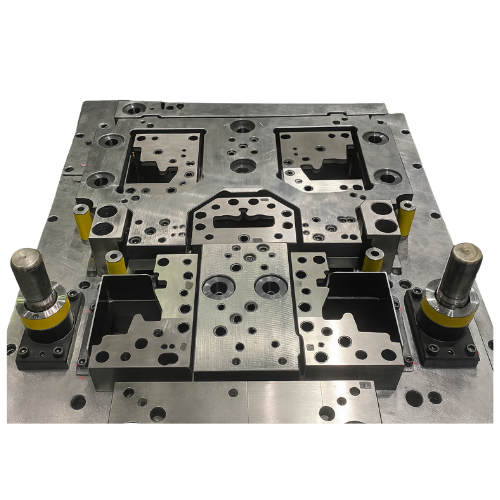

High-Performance Stamping Die for Precision Metal Forming

Stamping Mold

Typical Mold Steel Grades

Cr12MoV, SKD11, DC53

Estimated Lifespan

≥1,000,000 shots

Custom material sourcing to match your project needs.

Types of Stamping Dies

We offer a wide range of stamping dies tailored to your production needs:

- Progressive Dies–High-speed, multi-step tooling ideal for complex, high-volume parts.

- Compound Dies–Single-stroke dies that perform multiple operations simultaneously, perfect for flat components.

- Drawing Dies–Designed for deep drawing applications to create seamless cylindrical or box-shaped parts.

- Forming & Bending Dies–For shaping and bending metal into precise geometries.

- Blanking & Piercing Dies–Used for cutting and punching accurate holes or profiles in sheet metal.

Why Choose Us

20+ years of manufacturing experience

Advanced machines & strict quality control

ISO 9001 & IATF 16949

Design to finished product

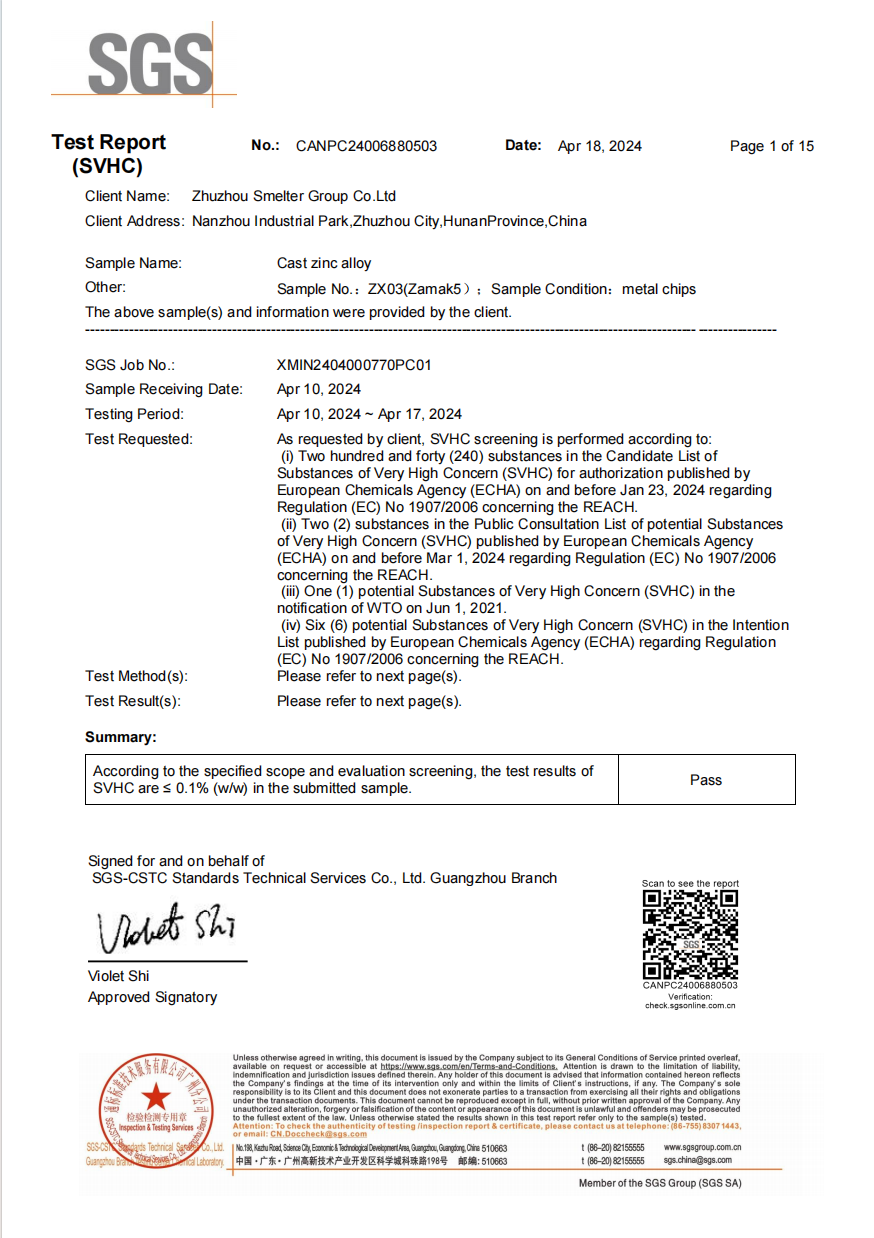

Compliant with RoHS & REACH

Dedicated project tracking and global delivery

Ready to work with a trusted mold design & manufacturing partner?

FAQ – Frequently Asked Questions

Q:What is the typical lead time for a custom stamping die?

A:Our average lead time ranges from 4 to 8 weeks, depending on die complexity and production requirements.

Q:What industries do your stamping dies serve?

A:We design and manufacture stamping dies for automotive, electronics, appliances, and industrial equipment sectors.

Q:How do you ensure stamping die quality?

A:We use advanced CAD/CAE tools, precision CNC machining, and conduct comprehensive inspections including CMM testing and die tryouts before delivery.

Q:Can you provide prototype stamping dies?

A:Yes, we offer prototype tooling solutions for testing and small-batch production prior to full-scale manufacturing.

Q:What is the expected lifespan of your stamping dies?

A:With proper maintenance, our stamping dies can achieve 500,000 to over 1,000,000 strokes, depending on material and application.

Recent Blog Posts

需要添加几篇文章这里再引用