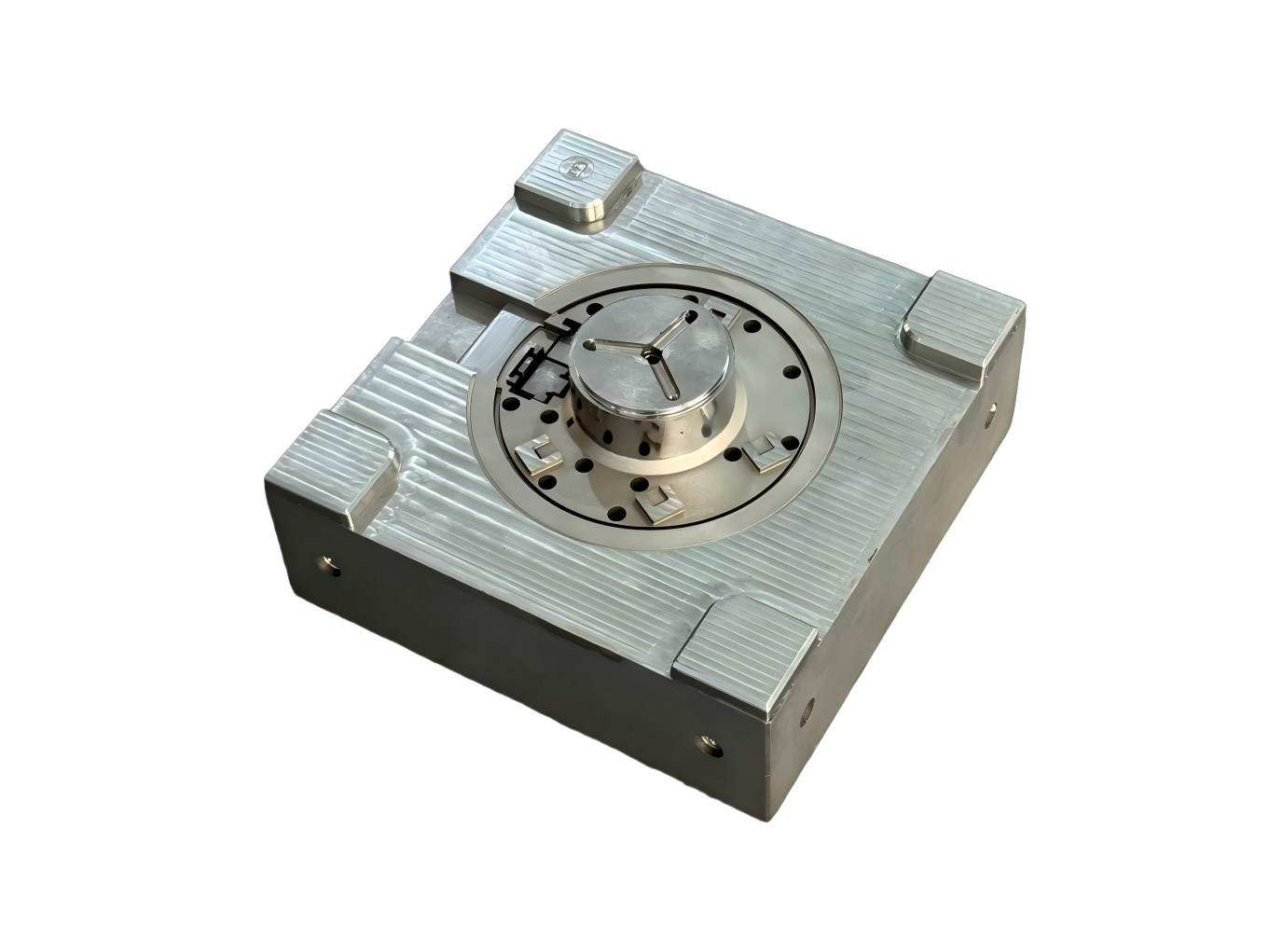

Die Casting Mold

Precision Tooling for High-Volume Production

- Certifications ISO 9001:2015 | IATF 16949

Why is Mold Important for Die Casting?

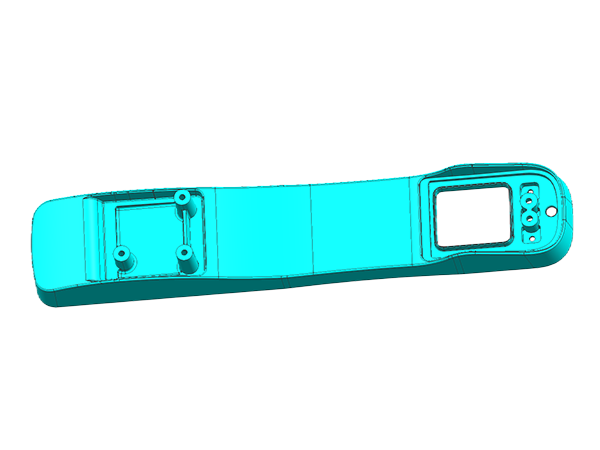

In die casting, the mold is critical. It defines the precision, surface quality, and production efficiency of every part. A well-designed die casting mold ensures:

- Consistent Accuracy– Tight tolerances across high-volume production

- Faster Cycle Times– Optimized cooling systems for higher productivity

- Cost Savings– Longer mold life and fewer defects

- Defect Prevention– Better gating and venting to avoid porosity and shrinkage

Your die casting success starts with the right mold.

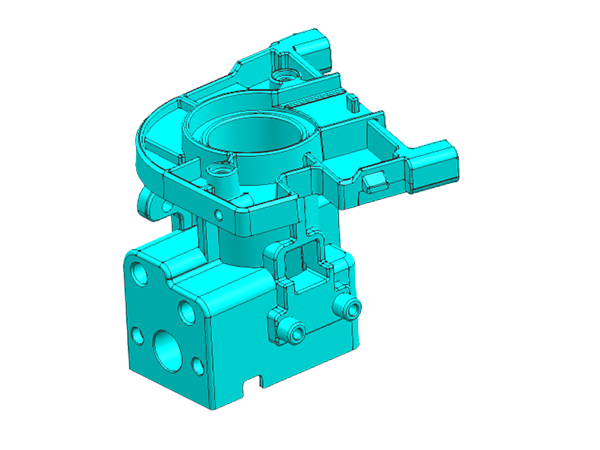

Our Capabilities: Built to Deliver Excellence

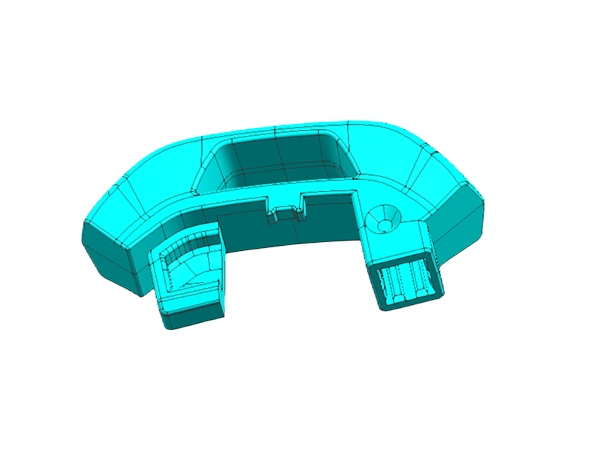

- Solutions for complex geometries and high-volume production

- 20+ years of die casting and precision tooling experience

- DFM analysis for cost-effective, high-quality results

- Tolerances up to ±0.01 mm after machining

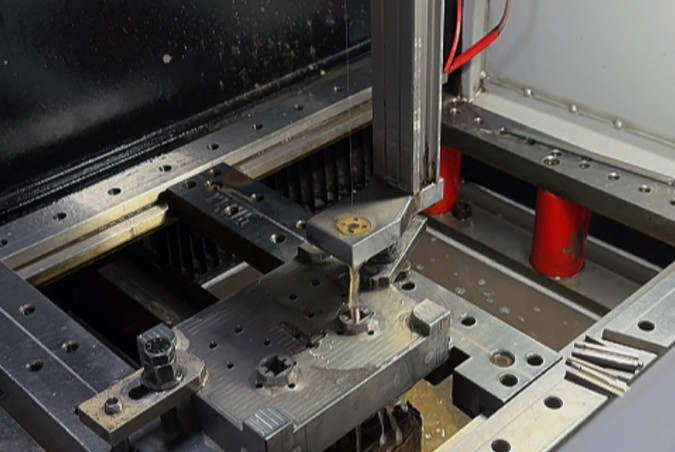

- EDM finishes to Ra < 0.8 µm for excellent cavity surfaces

- Serving Automotive, Industrial, Construction, Electronics, and New Energy sectors

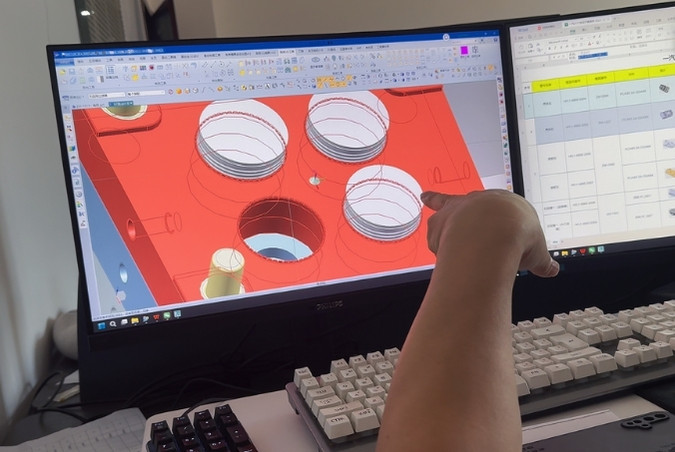

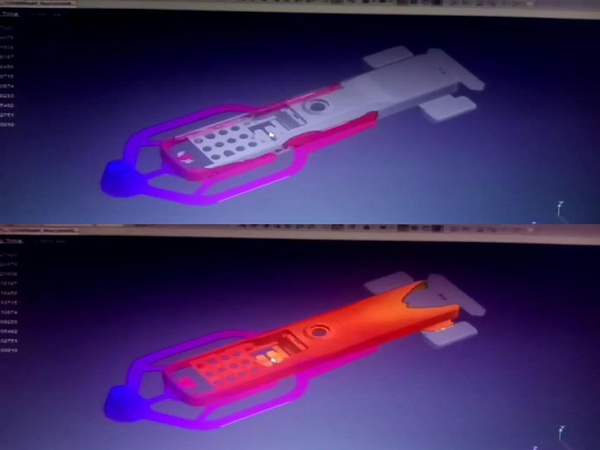

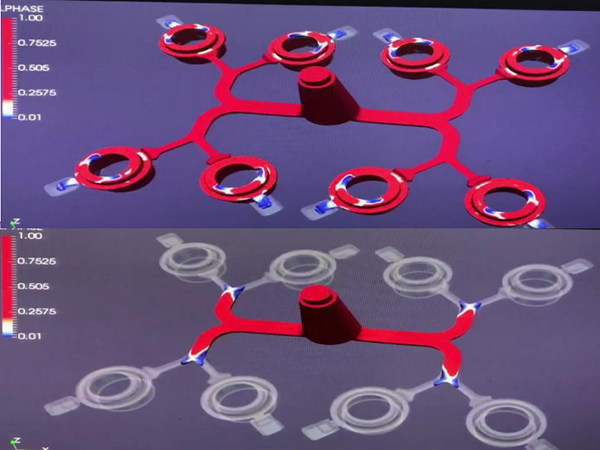

- CAD/CAM and Moldflow for optimized designs and faster lead times

- In-house CNC center for high-precision mold production

- Dedicated mold assembly and storage facilities

- ISO 9001:2015 & IATF 16949 certified

- SPC monitoring and CMM inspections for consistent precision

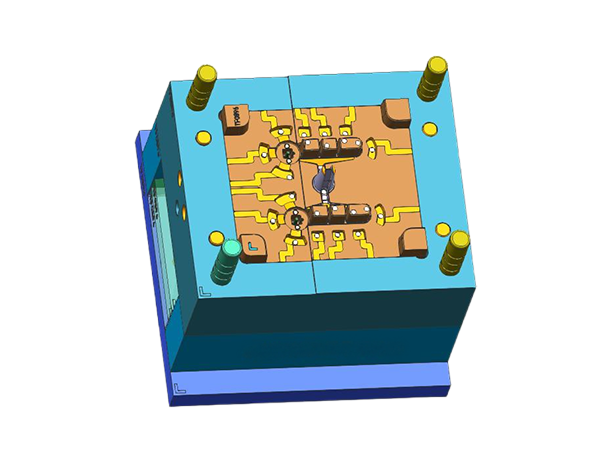

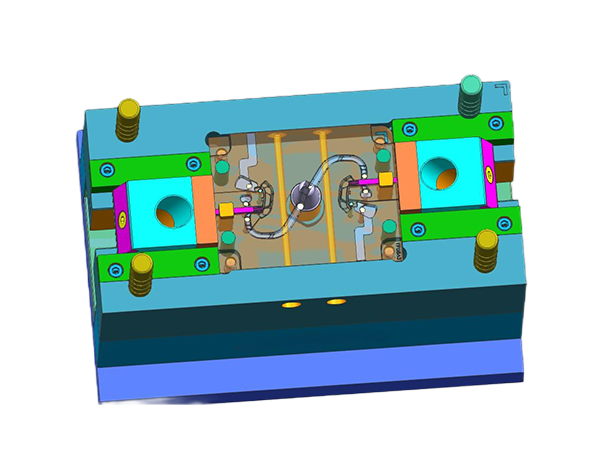

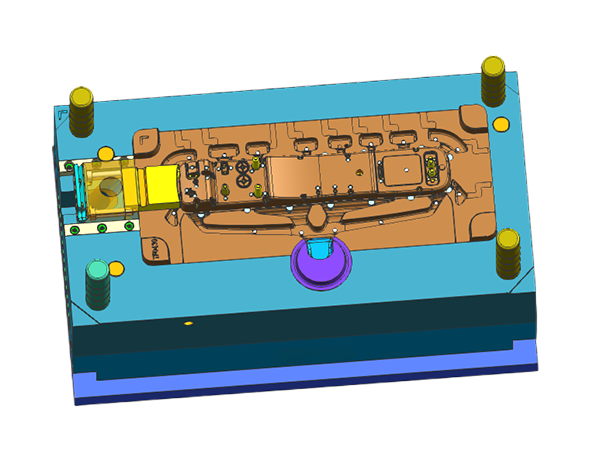

Mold Types for Die Casting

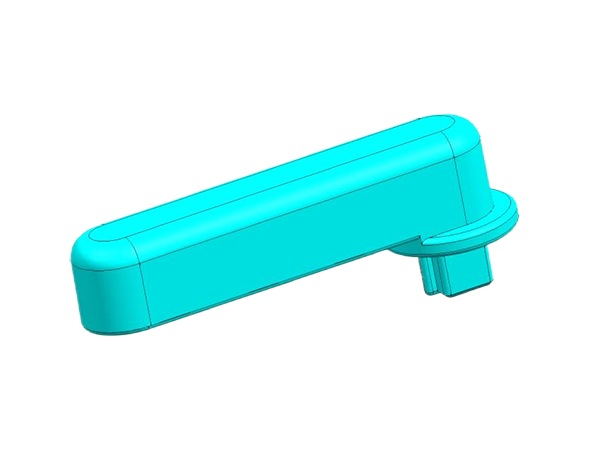

We design and build molds tailored to product structure, volume, and tolerance:

- Single-Cavity Mold–For medium/large parts

- Multi-Cavity Mold–For high-volume small parts

- Family Mold–Multiple parts in one cycle

- Insert Mold–Embedded components in die casting

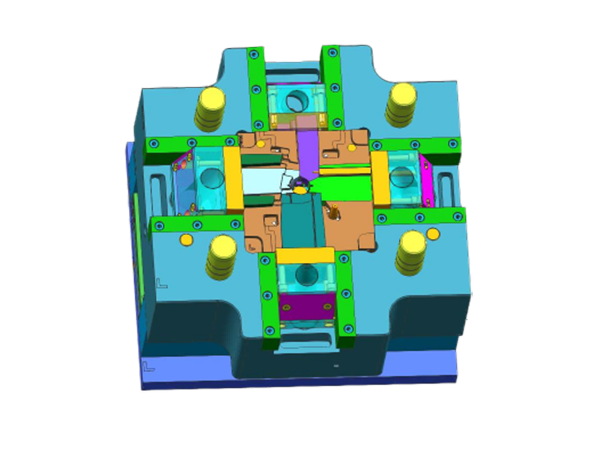

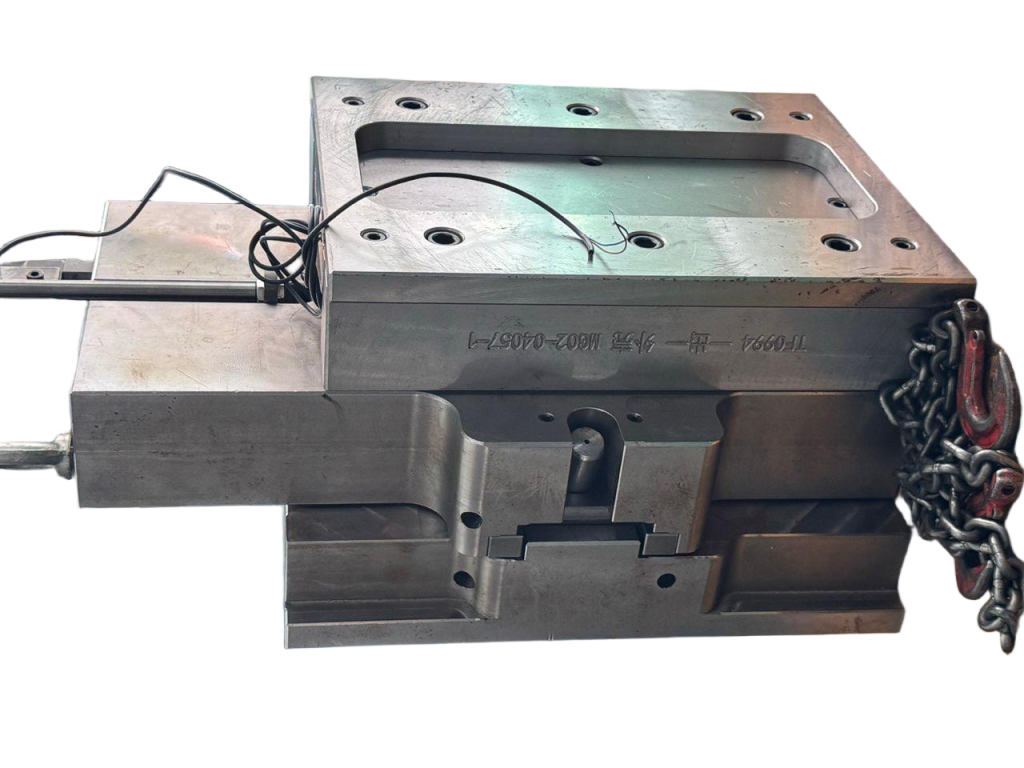

- Slide/Core-Pulling Mold–For undercuts, side holes, and complex geometries

In-house CAD and Moldflow optimization ensures both cost and performance.

Why Is Moldflow Analysis Critical for Die Casting Mold Design?

Discover how Moldflow helps prevent defects, optimize cooling, and deliver precision-engineered molds.

Want a mold design that prevents defects from the start?

Zinc and Aluminum Die Casting Mold Materials

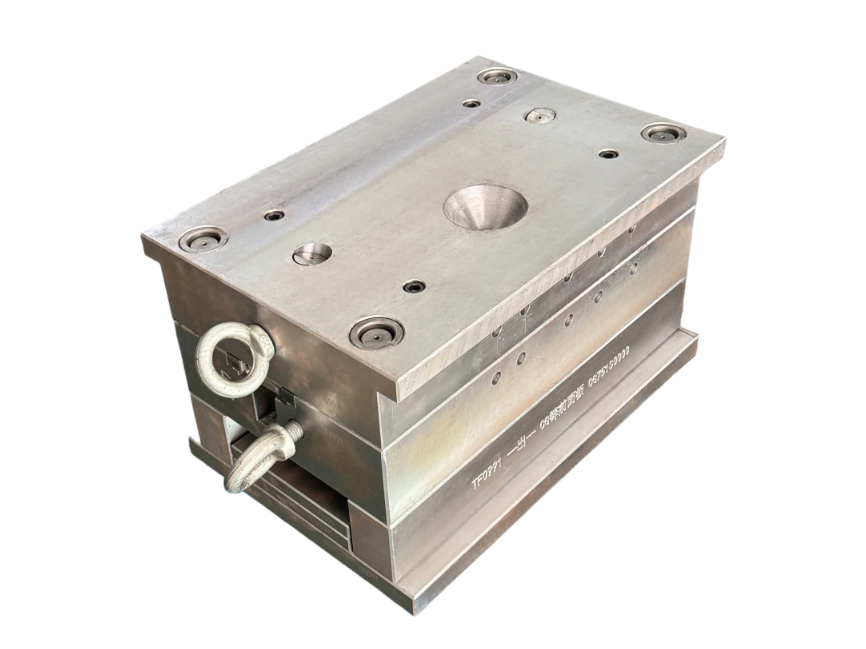

Hot Chamber Die Casting Mold (Zinc Alloy)

Typical Mold Steel Grades:

H13, 8407, 2344 ESR

Estimated Lifespan:

Up to 500,000 shots

Cold Chamber Die Casting Mold (Aluminum Alloy)

Typical Mold Steel Grades:

H13, 8407, QRO90, ADC3

Estimated Lifespan:

Up to 80,000 shots

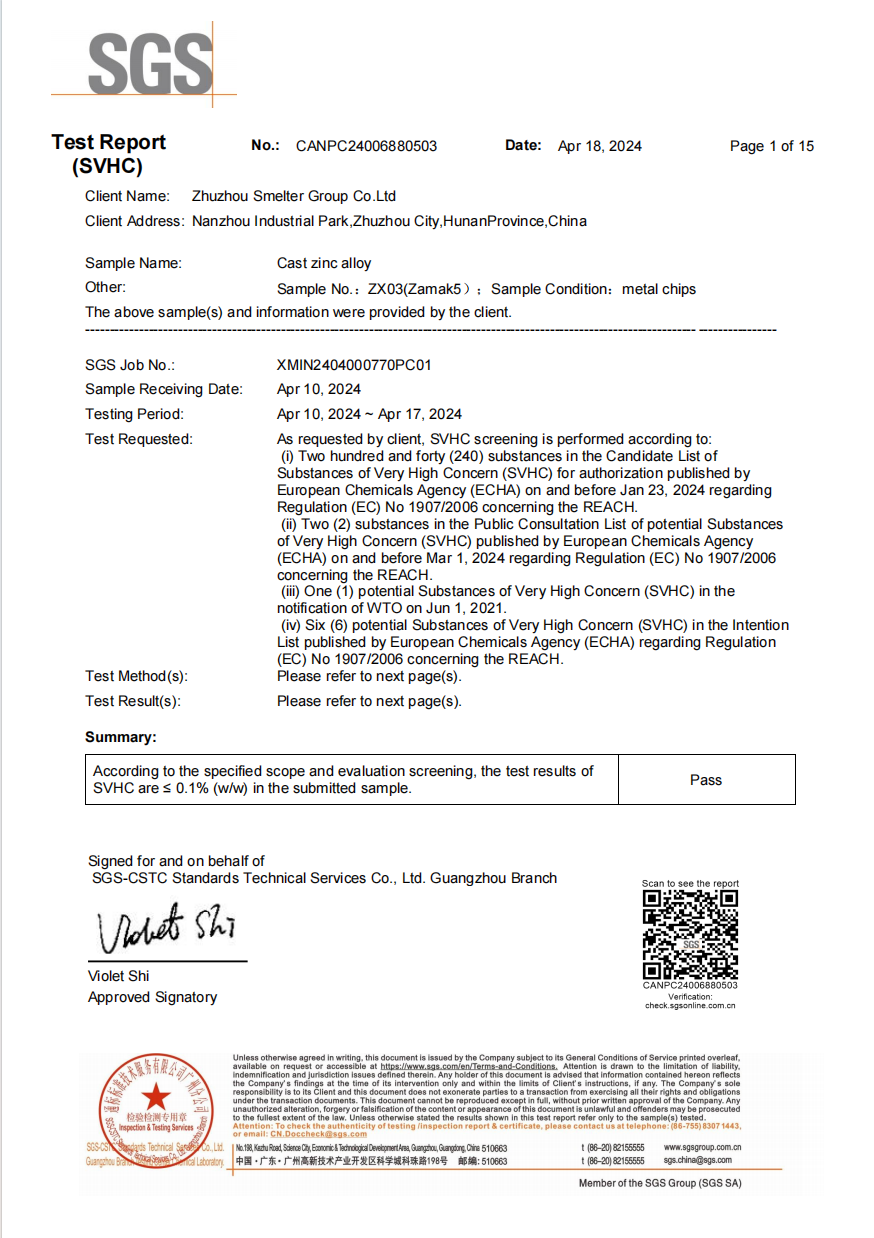

Why Choose Us

20+ years of manufacturing experience

Advanced machines & strict quality control

ISO 9001 & IATF 16949

Design to finished product

Compliant with RoHS & REACH

Dedicated project tracking and global delivery

Ready to work with a trusted mold design & manufacturing partner?

FAQ – Frequently Asked Questions

Q:What makes your die casting molds different from others?

A:Our molds are engineered with Moldflow simulation, advanced CAD/CAM design, and premium steel grades (H13, 8407, QRO90) to deliver exceptional durability and precision—meeting the demands of high-volume production.

Q:Do you provide prototyping services before final mold production?

A:Yes. We offer rapid prototyping and soft tooling solutions to validate your designs, reduce development time, and minimize risks before moving to full-scale die casting.

Q:Can you handle both hot chamber and cold chamber die casting molds?

A:Absolutely. We specialize in both hot chamber molds for zinc alloys, and cold chamber molds for aluminum alloys, ensuring the right solution for your specific application.

Q:How do you manage complex mold designs with undercuts and side actions?

A:Our team uses slider/core-pulling designs, combined with precision CNC machining and Moldflow analysis, to achieve accurate results even for parts with complex geometries and undercuts.

Q:What quality certifications do your processes follow?

A:All our operations are ISO 9001:2015 and IATF 16949 certified. We also implement SPC monitoring and advanced CMM inspections for consistent quality assurance.

Q:How long does a typical die casting mold last?

A:Lifespans vary by alloy and application. Zinc alloy molds typically achieve 300,000–500,000 shots, while aluminum alloy molds last 60,000–80,000 shots with proper maintenance.

Q:Do you offer surface finishing options for die-cast parts?

A:Yes. We provide a variety of finishing options, including polishing, powder coating, anodizing, and PVD plating, ensuring your parts meet both functional and aesthetic requirements.

Q:How quickly can you deliver molds for urgent projects?

A:Lead times depend on complexity, but we can provide expedited services for urgent projects with priority scheduling and streamlined in-house production.

Recent Blog Posts

需要添加几篇文章这里再引用