Custom Mold Making Services

High-Precision Injection, Die Casting, and Stamping Tooling Tailored to Your Manufacturing Needs

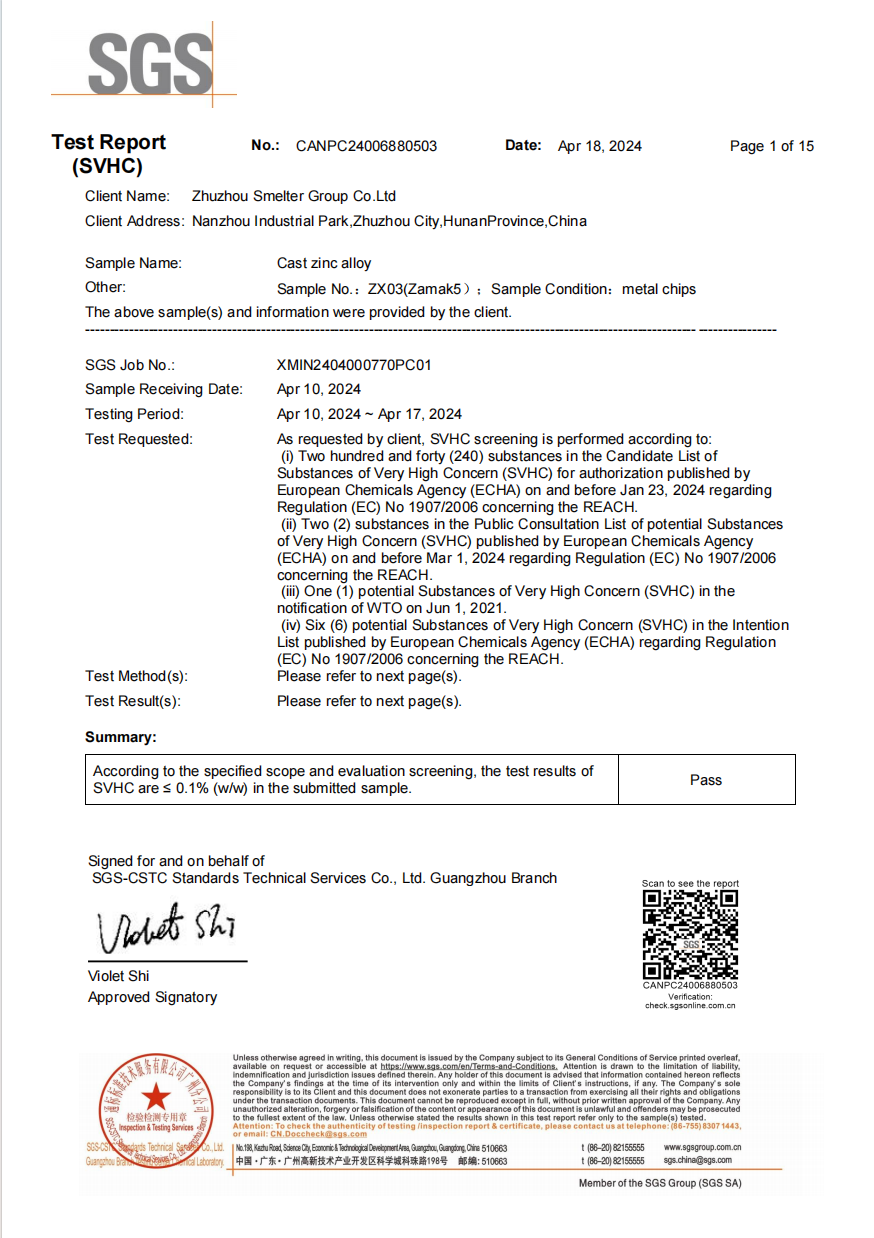

- Certifications ISO 9001:2015 | IATF 16949

1.What Are Molds and What Are They Used For?

Molds are precision-engineered tools used to shape materials into specific parts or components by injecting, pressing, or casting raw materials into a custom cavity. Molds are essential in manufacturing for producing consistent, repeatable, and dimensionally accurate parts across various industries.

Our Mold Making Capabilities

We provide end-to-end prototyping services using multiple methods, allowing your product designers to choose the right technology for each stage of development:

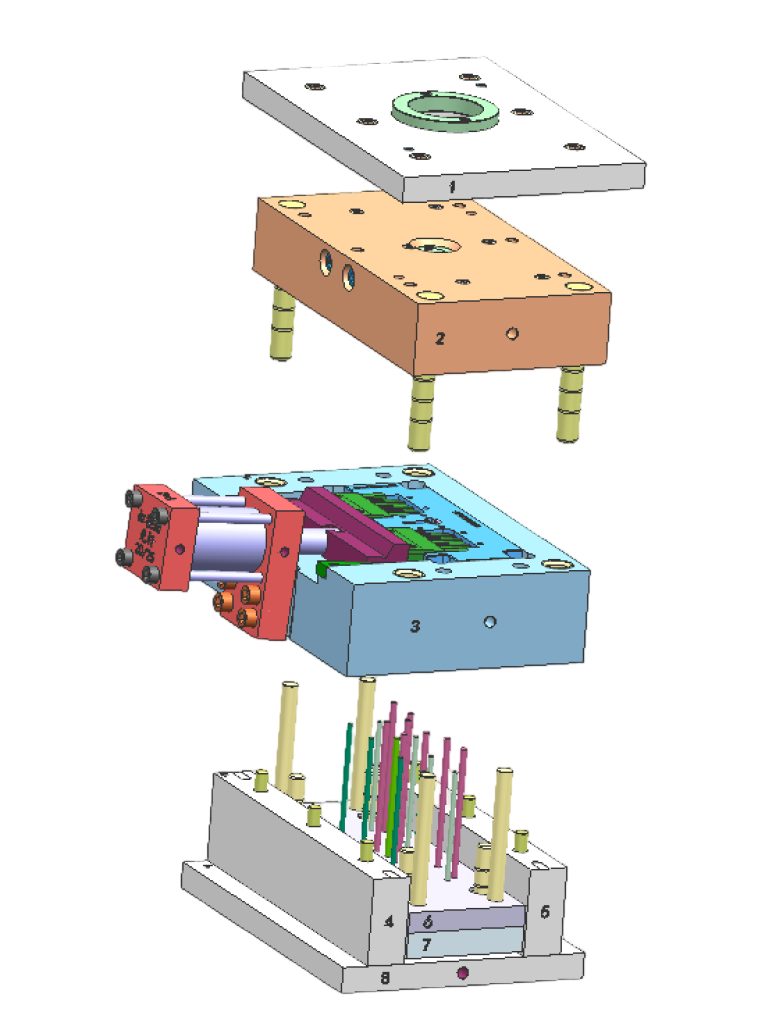

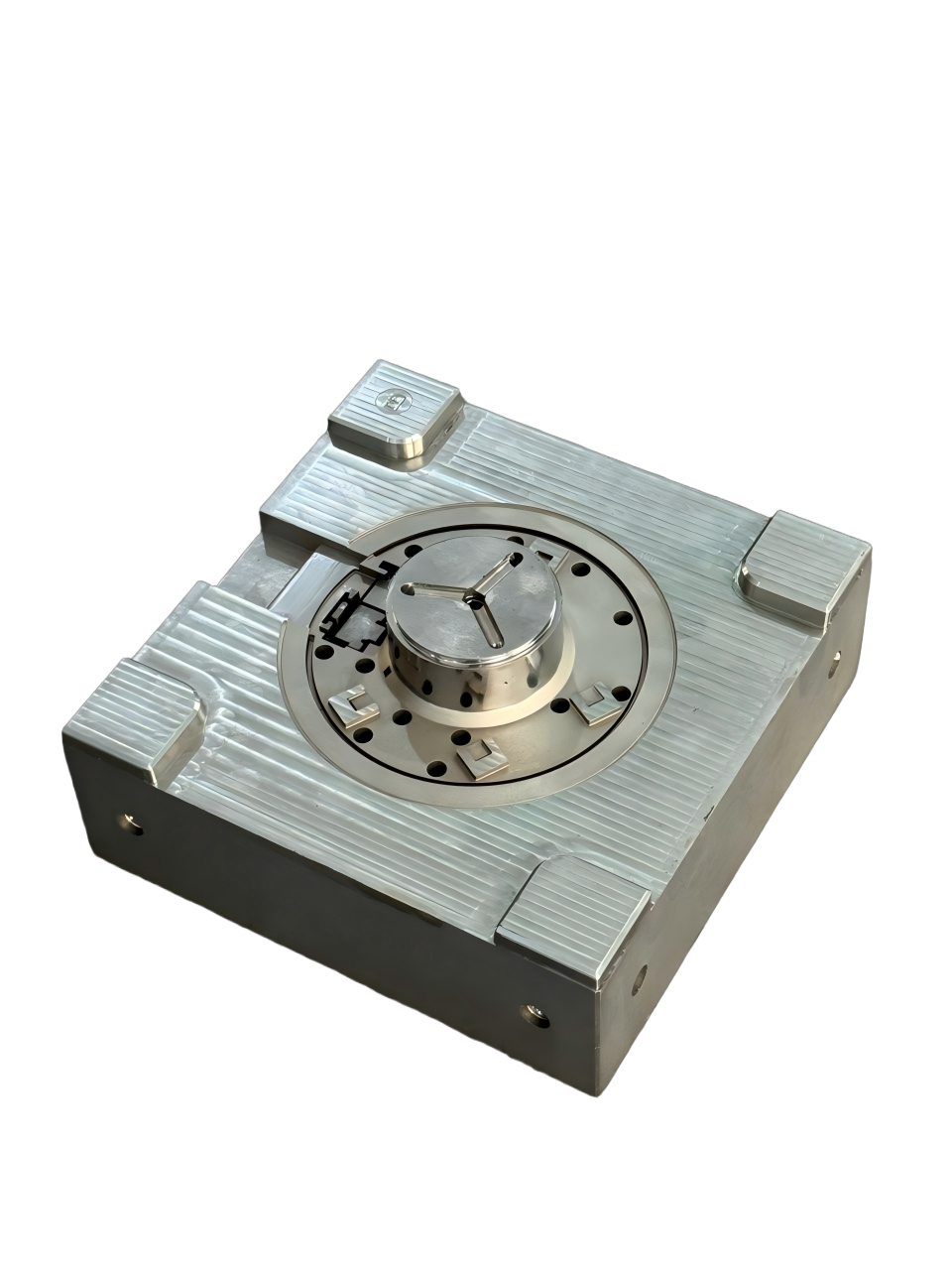

Injection Molds

for producing plastic parts in high volume

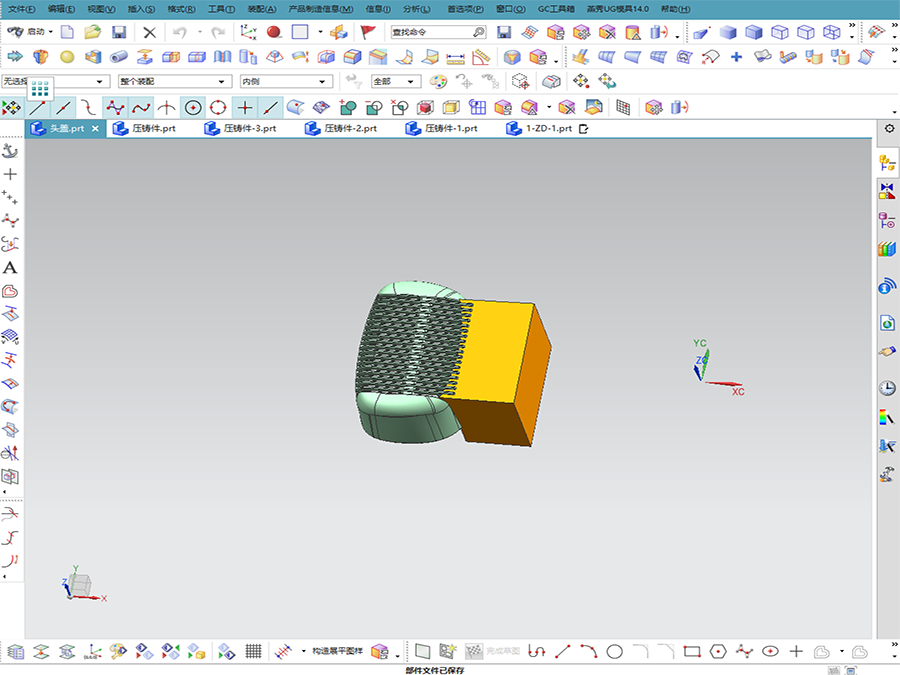

Die Casting Molds

ideal for zinc and aluminum alloy parts

Stamping Dies

for precision sheet metal components

Comprehensive Mold Types We Offer

From Plastic Injection to Metal Stamping

Categories | Materials |

Hot Runner Mold | Metal & Plastic |

Multi-Cavity Mold | Metal & Plastic |

Insert Mold | Metal & Plastic |

Slider Mold | Metal |

Precision Gear Mold | Metal & Plastic |

Cold Runner Mold | Plastic |

Progressive Die Mold | Sheet Metal Stamping Parts |

Rotary Table Mold | Metal & Plastic |

Precision Cooling Mold | Metal & Plastic |

Composite Mold | Metal & Plastic |

Slider Core-Pulling Mold | Metal & Plastic |

Hot Runner Multi-Cavity Injection Mold | Metal & Plastic |

Our Mold Manufacturing Process

From concept to completion, our mold making process includes:

- Product Feasibility Review & DFM (Design for Manufacturability) Analysis

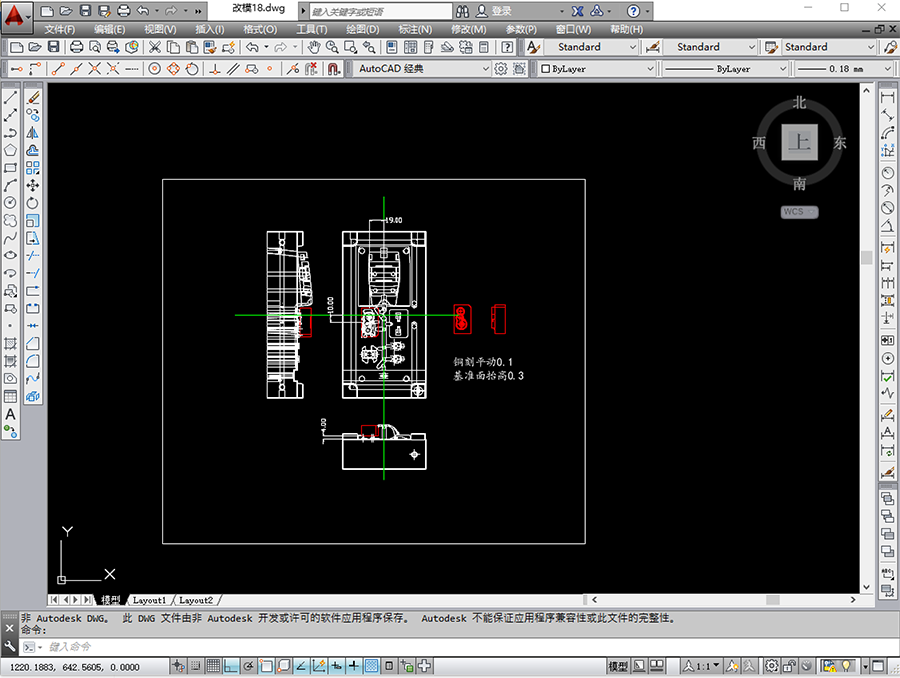

- 3D CAD Mold Design using advanced software

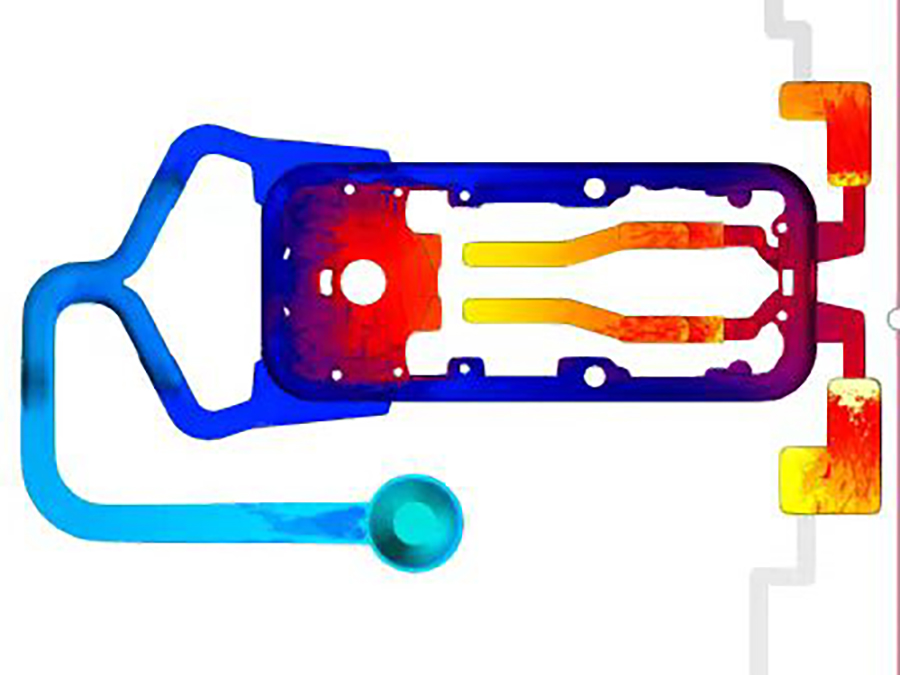

- Moldflow Analysis to simulate and optimize mold performance

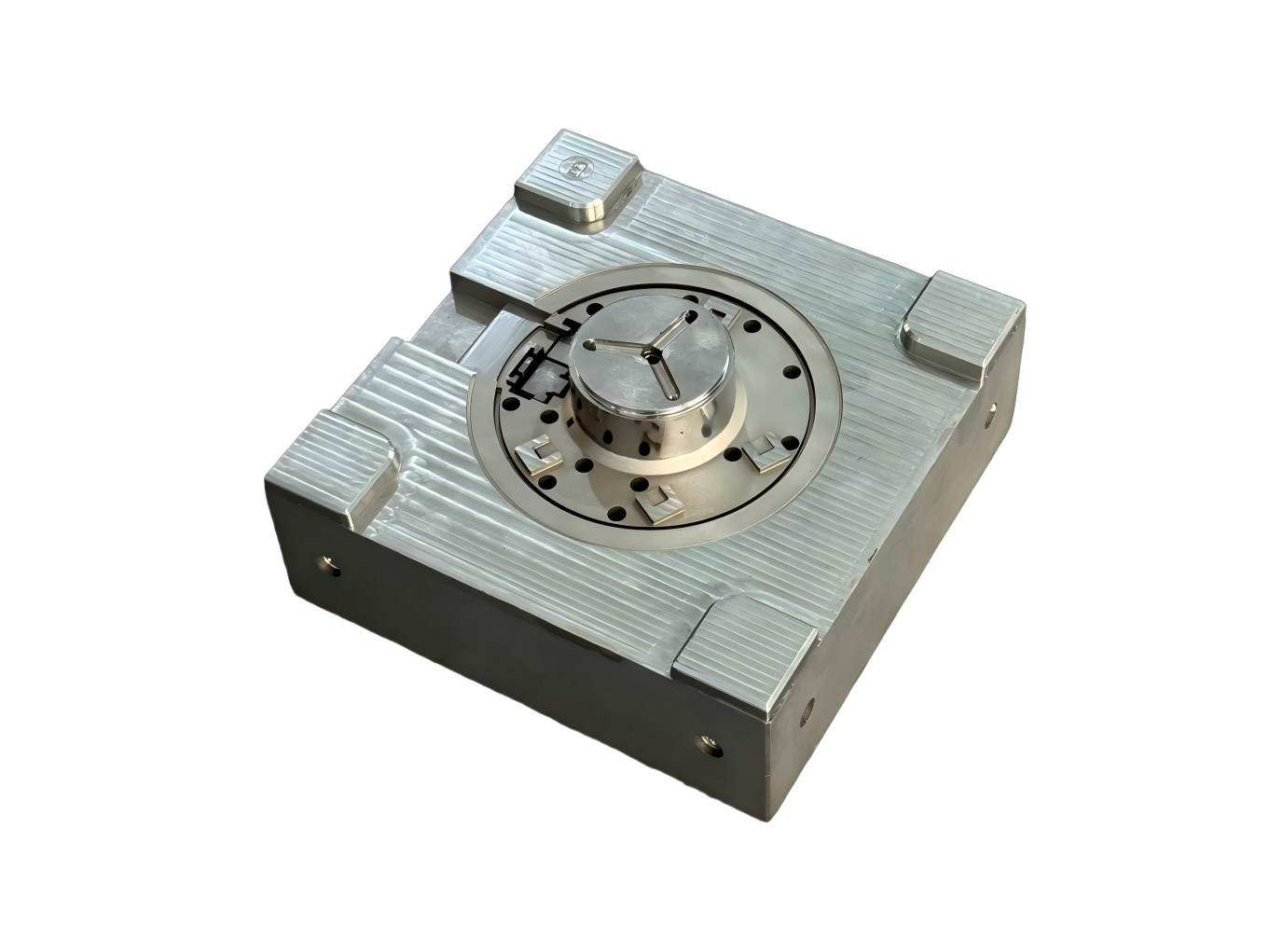

- High-precision CNC machining and EDM

- Mold assembly, testing, and verification

- Final polishing and readiness for mass production

Why Molds Matter for Mass Production

Molds are the foundation of scalable, cost-effective production. A well-designed mold ensures:

- Consistent part quality and dimensional accuracy

- Shorter cycle times and higher production efficiency

- Fewer downstream defects and less waste

High-quality molds reduce the total cost of ownership and accelerate time-to-market.

What We Provide

Professional Mold Design

Detailed 3D models with precision tolerancing to ensure accurate fit and function.

DFM Analysis

Identify design improvements early to enhance manufacturability and reduce costs.

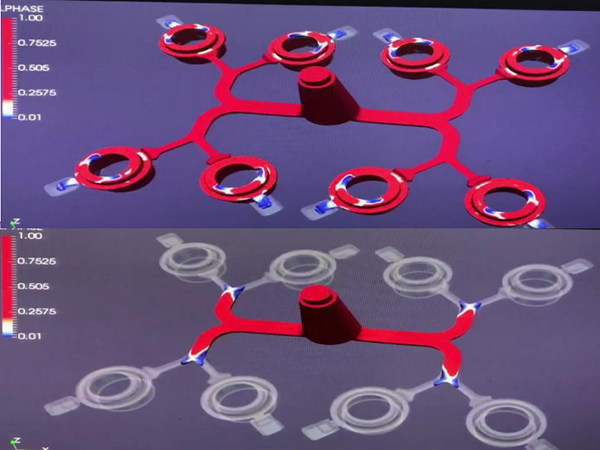

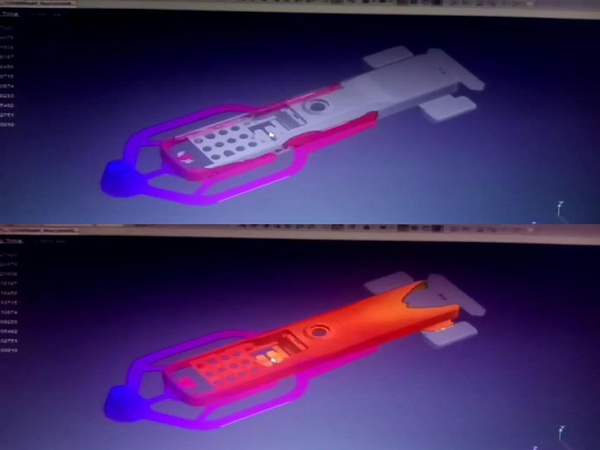

Moldflow Simulation

Predict flow behavior to eliminate warpage, sink marks, and short shots before tooling.

Proactive Mold Maintenance

Ongoing maintenance support to extend mold life and ensure consistent performance.

High-Precision Machining Capabilities

Wire Cutting Accuracy: ±0.01 mm

Ensures perfect fit and tight tolerance for high-precision molds.

EDM Surface Finish: Ra < 0.8 µm

Delivers smooth cavity surfaces, reducing defects and post-processing.

Mold Design Strengths

- Long service life with stable, repeatable performance.

- Mold flow-optimized to prevent shrinkage, porosity, and misfill.

- Delivers high accuracy and surface quality from the first shot.

Moldflow Success Stories

Moldflow simulation optimized gate and vent layout to ensure smooth filling, eliminate porosity, and achieve precise dimensions.

Result: Leak-free, consistent surface finish, and dimensional accuracy.

For this large and high-cosmetic zinc part, moldflow helped refine runner design and eliminate defects like air traps and weld lines.

Result: Enhanced yield and surface quality.

Why Choose Us

20+ years of manufacturing experience

Advanced machines & strict quality control

ISO 9001 & IATF 16949

Design to finished product

Compliant with RoHS & REACH

Dedicated project tracking and global delivery

Ready to work with a trusted mold design & manufacturing partner?

FAQ – Frequently Asked Questions

Q1: What’s the typical lead time for mold making?

A:Lead times vary depending on the mold complexity, but most custom molds can be completed within 25 to 40 days.Expedited service is available for urgent needs.

Q2: Do you provide mold maintenance or modification services?

A:Yes, we offer full lifecycle support including maintenance, repairs, and engineering changes to extend your mold’s performance.

Q3: Can you work with overseas clients and ship molds internationally?

A:Absolutely. We serve clients globally and offer secure international shipping with proper packaging and documentation.

Q4: What industries do you serve with your mold making capabilities?

A:Our molds are used across industries including automotive, home appliances, medical devices, consumer electronics, and bathroom hardware.

Q5: Do you offer prototype molds for low-volume production?

A:Yes, we offer cost-effective prototype tooling for functional testing and limited production runs before investing in full-scale tooling.

Q6: How do you ensure the quality of the mold before delivery?

A:Every mold undergoes dimensional inspection, material verification, and trial runs to ensure it meets the design and performance requirements.

Q7: What information do you need to provide a mold quotation?

A:We typically require 3D CAD files (STEP or IGES), part specifications, estimated annual volume, and any special material or surface finish requirements.

Recent Blog Posts

需要添加几篇文章这里再引用