Rapid Sample Manufacturing Solutions

Rapid prototyping, CNC machining, and 3D printing to accelerate your product development.

- Certifications ISO 9001:2015 | IATF 16949

What is Sample Manufacturing?

Sample manufacturing is the process of producing prototype or low-volume parts to validate design, functionality, and manufacturability before full-scale production. It bridges the gap between concept and mass production, ensuring that your final product meets exact specifications.

Why is Sample Manufacturing Important?

Design Validation

Test and refine designs early to prevent costly mass production errors.

Faster Time-to-Market

Quickly create functional prototypes for testing and launch.

Cost Savings

Spot production issues and optimize processes before large-scale tooling.

Quality Assurance

Use approved samples (Golden Samples) to ensure consistent quality.Ready to Bring Your Ideas to Life?

Partner with us for fast, precise, and reliable sample manufacturing.

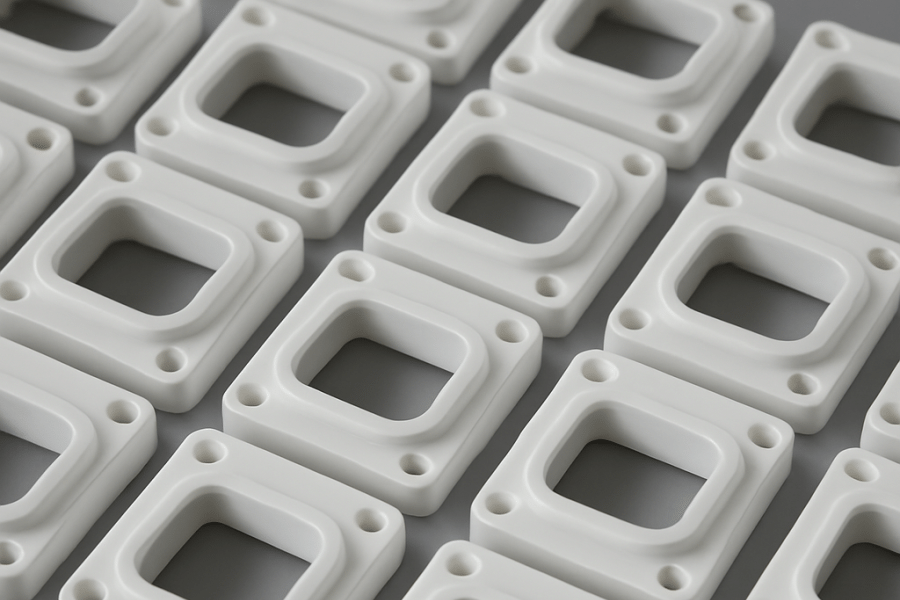

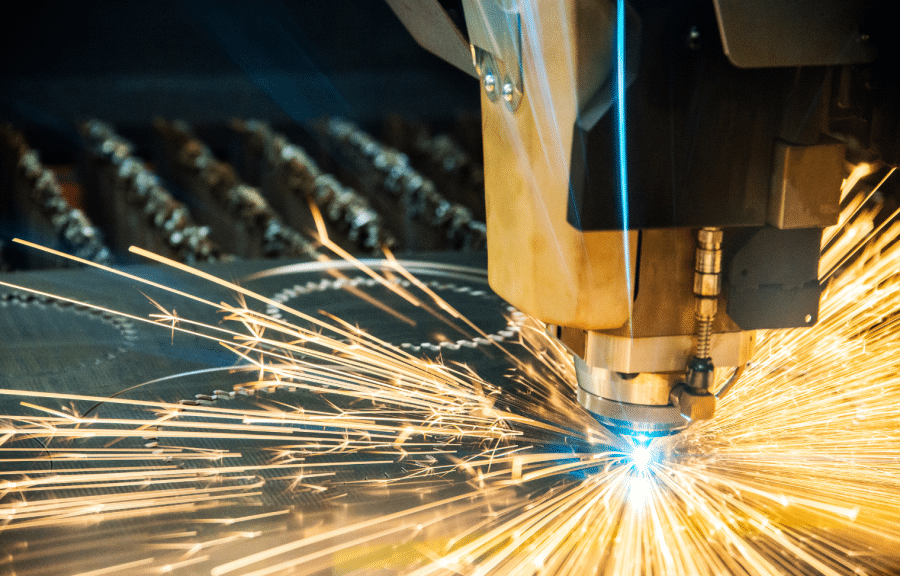

CNC Prototyping

High-precision metal and plastic prototypes with 3-and 4-axis machining.

3D Printing

Fast, cost-effective prototypes using SLA, SLS, and DMLS technologies.

Vacuum Casting

Low-volume polyurethane parts with silicone molds for design validation.

Why Choose Us for Sample Manufacturing?

Our Working Process – Sample Manufacturing

Initial Consultation & Project Assessment

We start by understanding your product requirements, timelines, and target markets. Our team assesses your project scope and offers tailored solutions.

Design Support & Engineering (ODM Optional)

For ODM projects, we provide design for manufacturability (DFM) support, CAD modeling, and prototype development to refine your product before mass production.

Tooling & Sample Production

We develop custom molds, dies, and tooling. Sample production ensures your specifications are met and provides an opportunity for design adjustments.

Scalable Mass Production (OEM)

With advanced facilities covering die casting, injection molding, CNC machining, and assembly, we deliver high-volume production with consistent quality.

Quality Assurance & Compliance

Each stage includes rigorous QC inspections and compliance with ISO 9001:2015, IATF 16949, and RoHS/REACH standards.

Assembly, Packaging & Global Delivery

We handle final assembly, custom packaging, and worldwide shipping to ensure your products arrive on time and ready for market.

Ready to turn your ideas into functional prototypes?

From concept to reality – we make sample manufacturing seamless.

Explore materials. Explore possibilities. Start your journey with us.

Applications in Multiple Industries

Empowering your success with advanced, high-quality solutions for every industry

Recent Blog Posts

需要添加几篇文章这里再引用