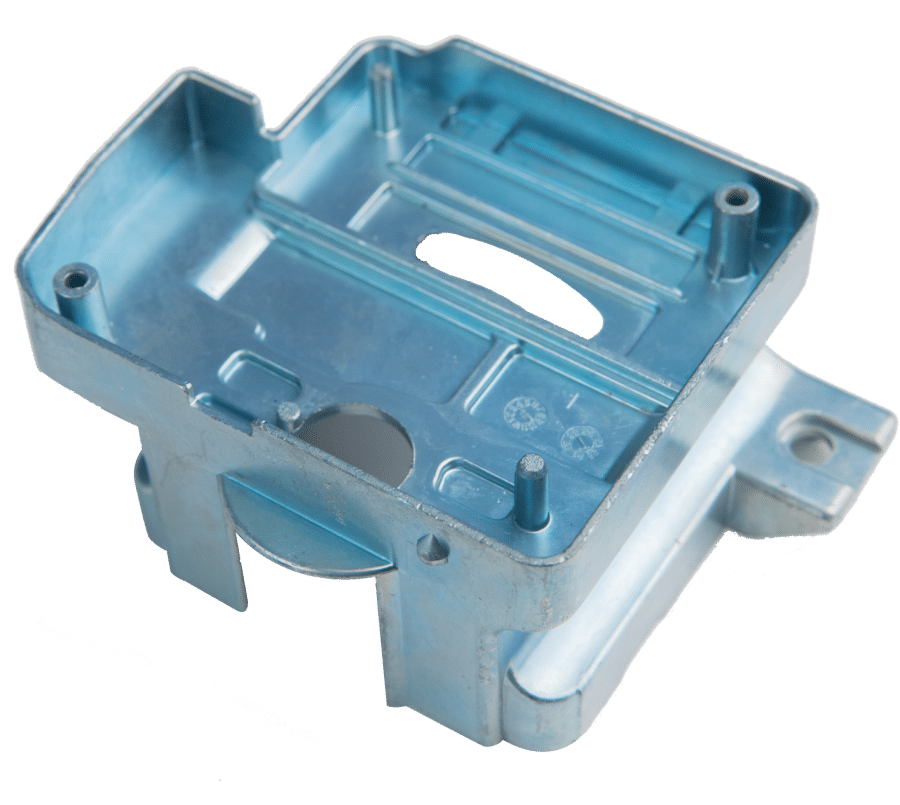

Precision Zinc Die Casting Services

End-to-End Zinc Die Casting Solutions for Automotive, Electronics & Hardware Industries

- Certifications ISO 9001:2015 | IATF 16949

What is Zinc Die Casting?

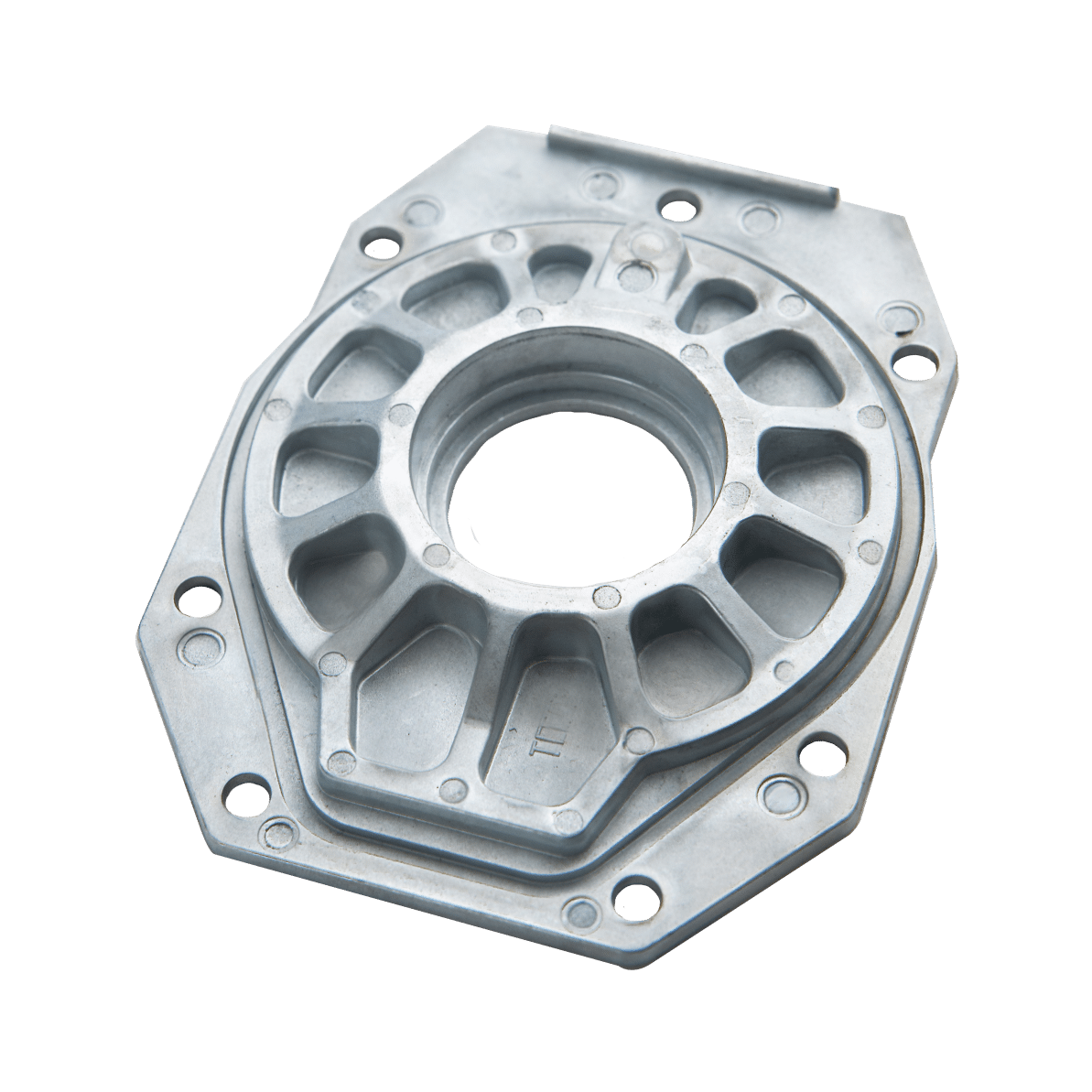

Zinc die casting is a high-precision metal forming process where molten zinc alloy is injected into a steel mold under high pressure to create complex, durable parts with excellent surface finish.

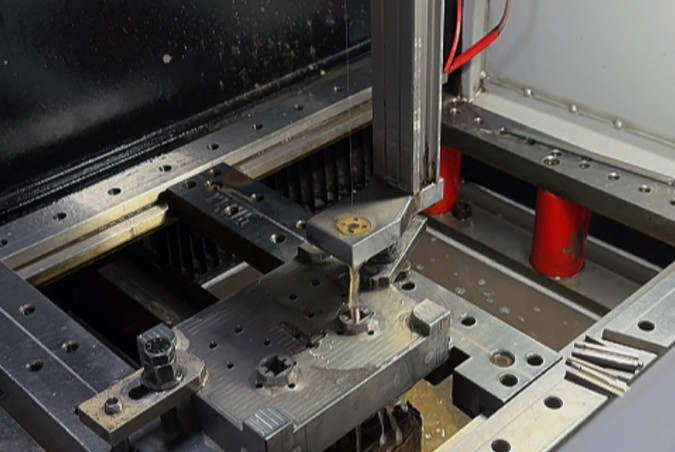

How Does Zinc Die Casting Work?

Using the hot chamber method, molten zinc is drawn directly into the injection system, enabling fast cycle times and high efficiency—ideal for producing small to medium-sized components at scale.

Key advantages:

precise, strong, and cost-effective solutions for high-volume small and medium-sized parts.

Our Zinc Die Casting Services & Capabilities

- 12+ Hot Chamber Die Casting Machines (up to 400T)

- In-house CNC machining center

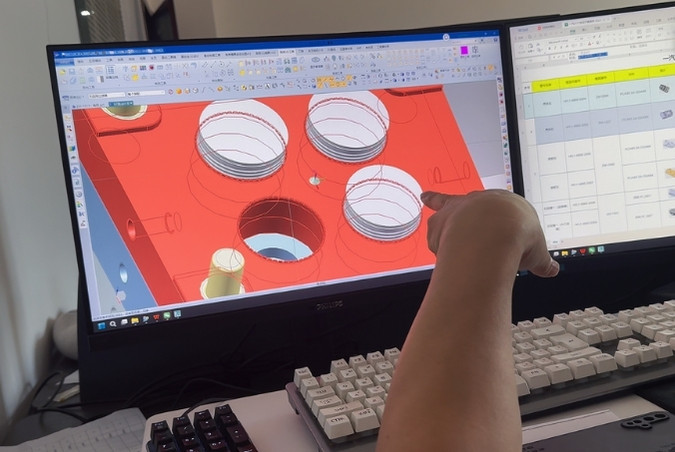

- CAD/CAM & Moldflow simulation for optimized designs

- Custom mold solutions for complex parts and high volumes

- 20+ years of engineering expertise

- Full DFM analysis to ensure cost-effective, high-quality production

- Tolerances: ±0.01 mm post-machining

- Batch Sizes: From prototypes to high-volume production

- Applications: Automotive, Industrial, Electronics, Energy

- ISO 9001:2015 & IATF 16949 certified

- SPC monitoring and CMM inspections for consistent precision

Zinc Alloy Grades & Properties

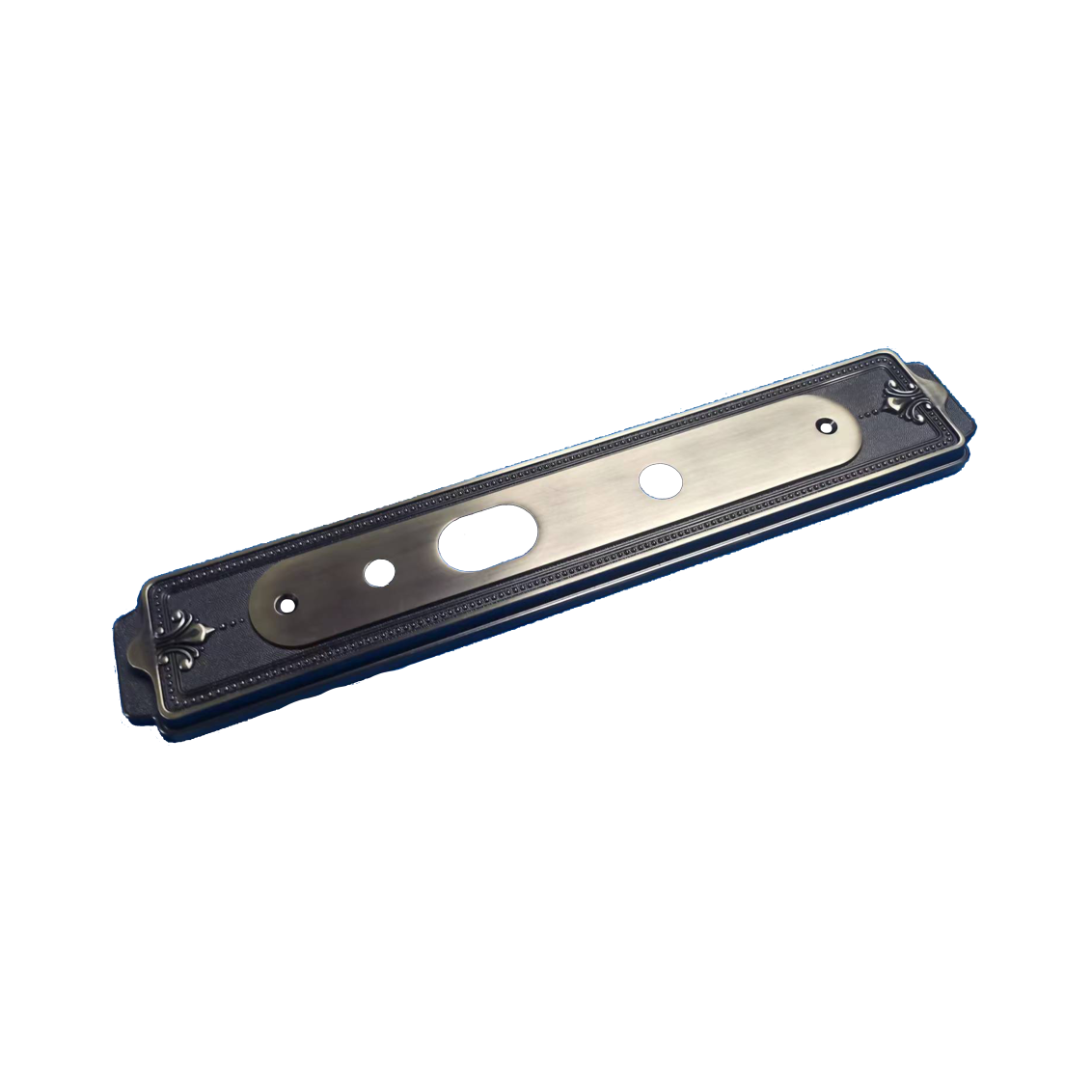

Zinc alloys, especially the Zamak series, are widely used in die casting for their excellent cast ability, strength, and surface finish.

We offer a full range of Zamak zinc alloys to suit different functional and mechanical requirements:

Alloy | Properties | Typical Use |

Excellent stability and corrosion resistance | General hardware, lock panels | |

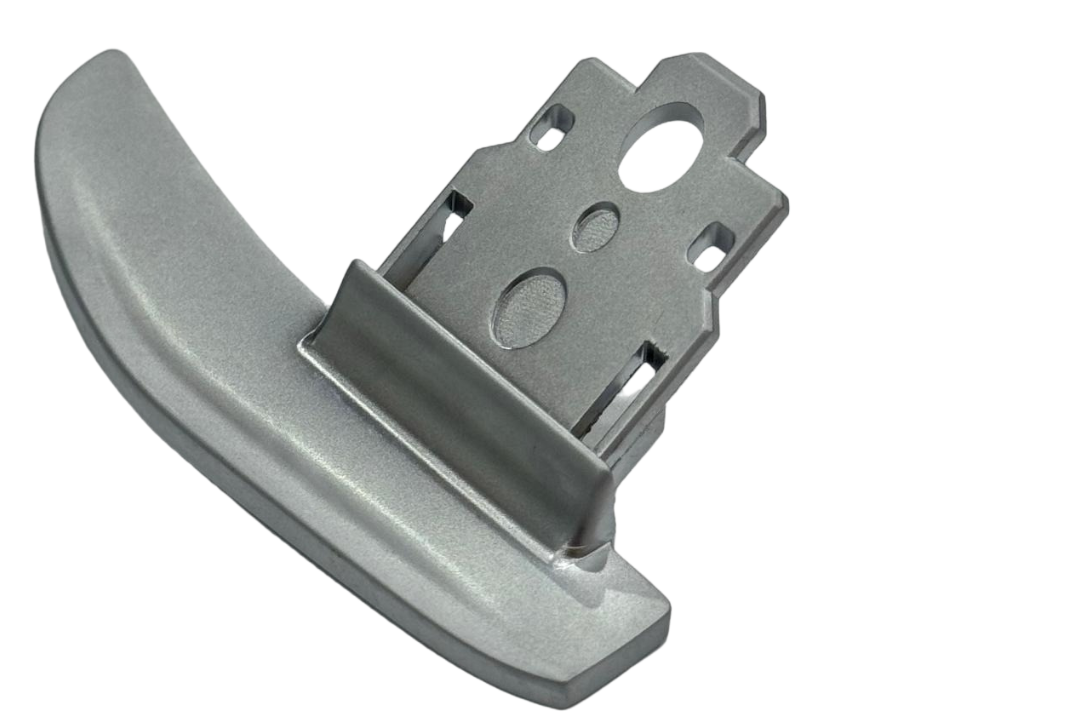

Higher strength and hardness (adds copper) | Automotive handles, mechanical parts |

All our materials comply with RoHS and REACH standards.

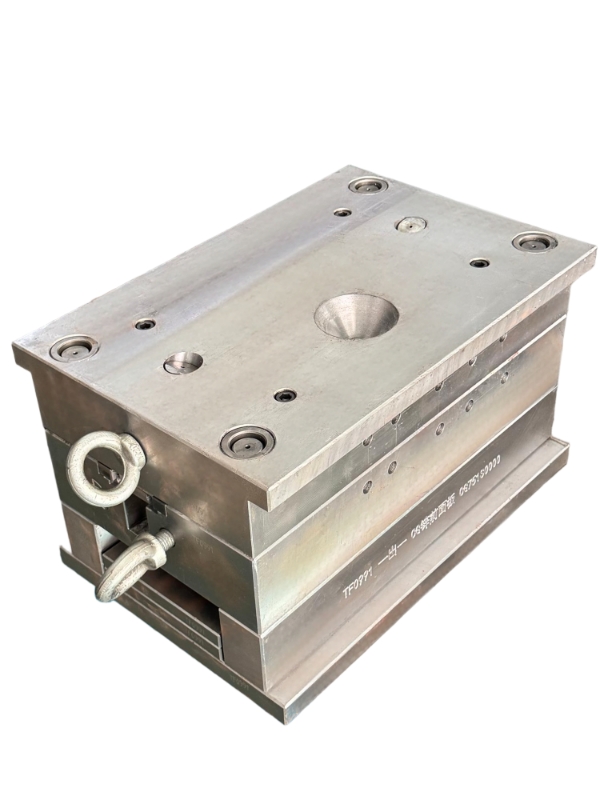

4.Mold Types for Zinc Die Casting

We designs and builds molds tailored to product structure, volume, and tolerance:

- Single-Cavity Mold–For medium/large parts

- Multi-Cavity Mold–For high-volume small parts

- Family Mold–Multiple parts in one cycle

- Insert Mold–Embedded components in die casting

- Slide/Core-Pulling Mold–For undercuts, side holes, and complex geometries

In-house CAD and Moldflow optimization ensures both cost and performance.

Why Is Mold Manufacturing Critical in Die Casting?

Mold design directly impacts product quality, cycle time, and tooling lifespan.

Surface Finishing Options

We provide diverse finishing solutions that combine aesthetics, functionality, and durability to meet the needs of various industries.

- Anodizing

- Polishing

- Electroplating

- PVD Coating

- Spray Painting

- Powder Coating

- Brushed Finish

- Antique Finish

Ready to elevate your aluminum castings with precision surface finishes?

Applications & Case Studies

Zinc alloy die cast parts are valued across industries for their strength, precision, and superior surface finish. Typical applications include:

- Automotive Components

- Consumer Electronics

- Home Hardware

- Industrial Equipment

- Telecommunication Devices

- Smart Devices

- New Energy Solutions

- Construction Hardware

Looking for a trusted partner for your zinc die cast parts?

Why Choose Us

20+ years of manufacturing experience

Advanced machines & strict quality control

ISO 9001 & IATF 16949

Design to finished product

Compliant with RoHS & REACH

Dedicated project tracking and global delivery

Ready to work with a reliable aluminum die casting partner?

FAQ – Frequently Asked Questions

Q1: What zinc alloys do you use?

A: Mainly Zamak 3 and Zamak 5, chosen for strength, corrosion resistance, and finish. Custom alloys are also supported.

Q2: What’s your typical mold lead time?

A: Standard molds take 25–40 days, depending on complexity. Rush options are available.

Q3: Can you assist with part design and mold development?

A: Yes. We offer DFM analysis, mold flow simulation, and custom mold design for optimal manufacturability and cost-efficiency.

Q4: How do you protect customer IP?

A: We maintain strict confidentiality and can sign NDAs before receiving drawings.

Q5: How is mold maintenance and storage handled?

A: All molds are maintained in-house with scheduled checks. Free storage is provided for active customers with maintenance logs available.

Q6: Are your products internationally compliant?

A: Yes. Materials meet RoHS, REACH, and other standards with certifications upon request.

Q7: How do you ensure quality?

A: We’re ISO 9001 and IATF 16949 certified, using SPC monitoring, CMM inspection, and detailed QC reports for every batch.

Q8: Do you handle global shipping?

A: Yes. We support FOB, CIF, DDP terms and assist with customs, Form E/CO documents, and logistics coordination.

Q9: Can zinc die cast parts be machined post-casting?

A: Absolutely. We offer CNC machining, tapping, reaming, and drilling for tighter tolerances.

Q10: What tolerances can you achieve?

A: Typical casting tolerances are ±0.05–0.10 mm; post-machining can achieve ±0.01 mm.

Q11: How do you control defects like porosity?

A: We use Moldflow analysis, optimized gating, and precise process controls, with X-ray or section testing as needed.

Q12: Do you accept OEM and ODM projects?

A: Yes. We have extensive OEM/ODM experience and provide full design and manufacturing support.

Recent Blog Posts

需要添加几篇文章这里再引用