High-Precision CNC Prototyping for Complex Designs

From one-off prototypes to production-ready parts, we deliver unmatched speed and accuracy.

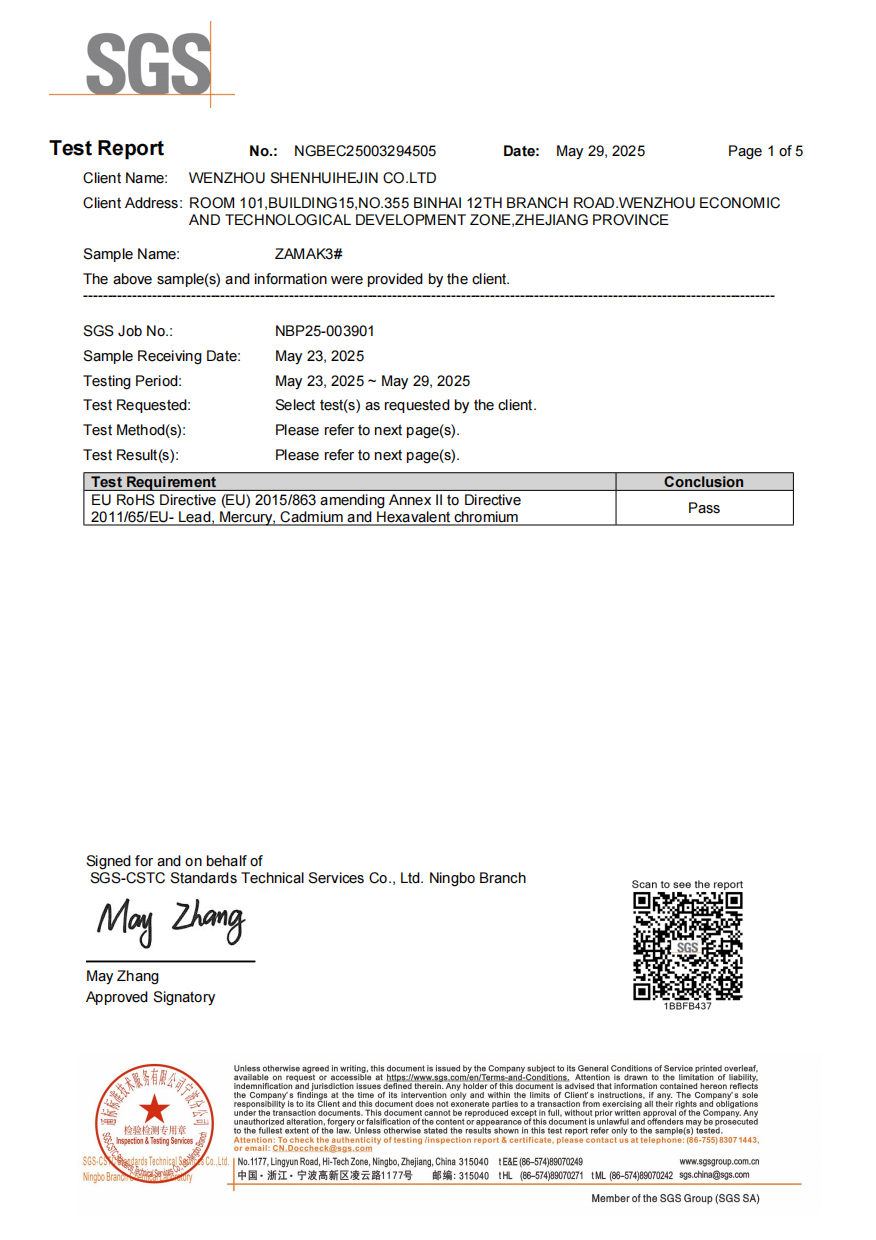

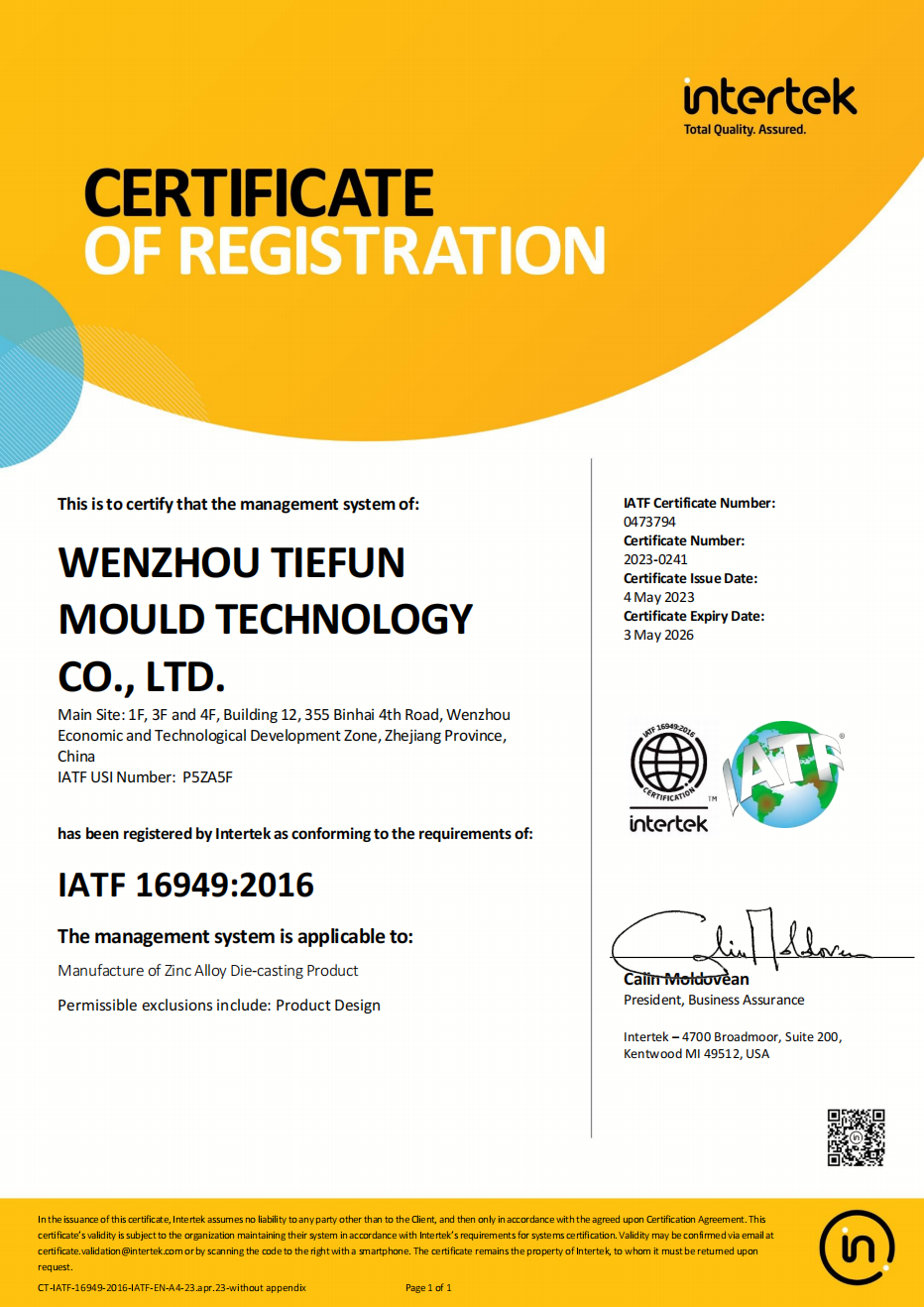

- Certifications ISO 9001:2015 | IATF 16949

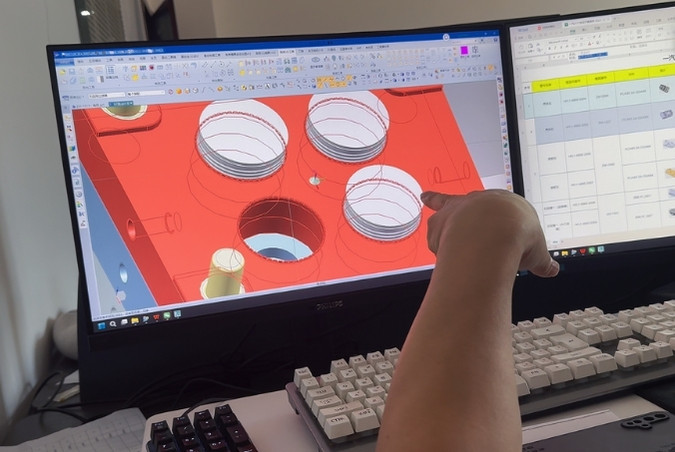

What is CNC prototyping?

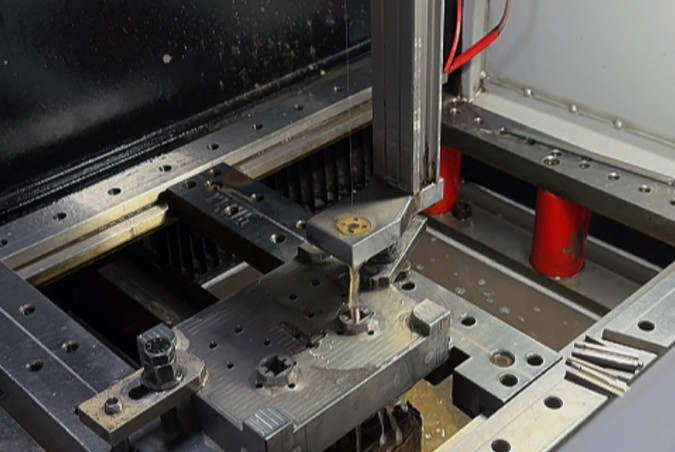

CNC prototyping is a rapid manufacturing process that uses computer-controlled machining to create precise, functional prototypes.

How It Works

The process involves milling or turning solid blocks of metal or plastic into highly accurate parts directly from 3D CAD models.

Key advantages

Fast, precise, and ideal for prototypes or small production runs.

Our CNC prototyping Services & Capabilities

- 10+ CNC milling machines (3- and 4-axis) for precision machining

- In-house CNC machining center

- CAD/CAM & Moldflow simulation for optimized designs

- Tolerances: ±0.01 mm post-machining

- Batch Sizes: From prototypes to high-volume production

- Applications: Automotive, Industrial, Electronics, Energy

- Custom mold solutions for complex parts and high volumes

- 20+ years of engineering expertise

- Full DFM analysis to ensure cost-effective, high-quality production

- ISO 9001:2015 & IATF 16949 certified

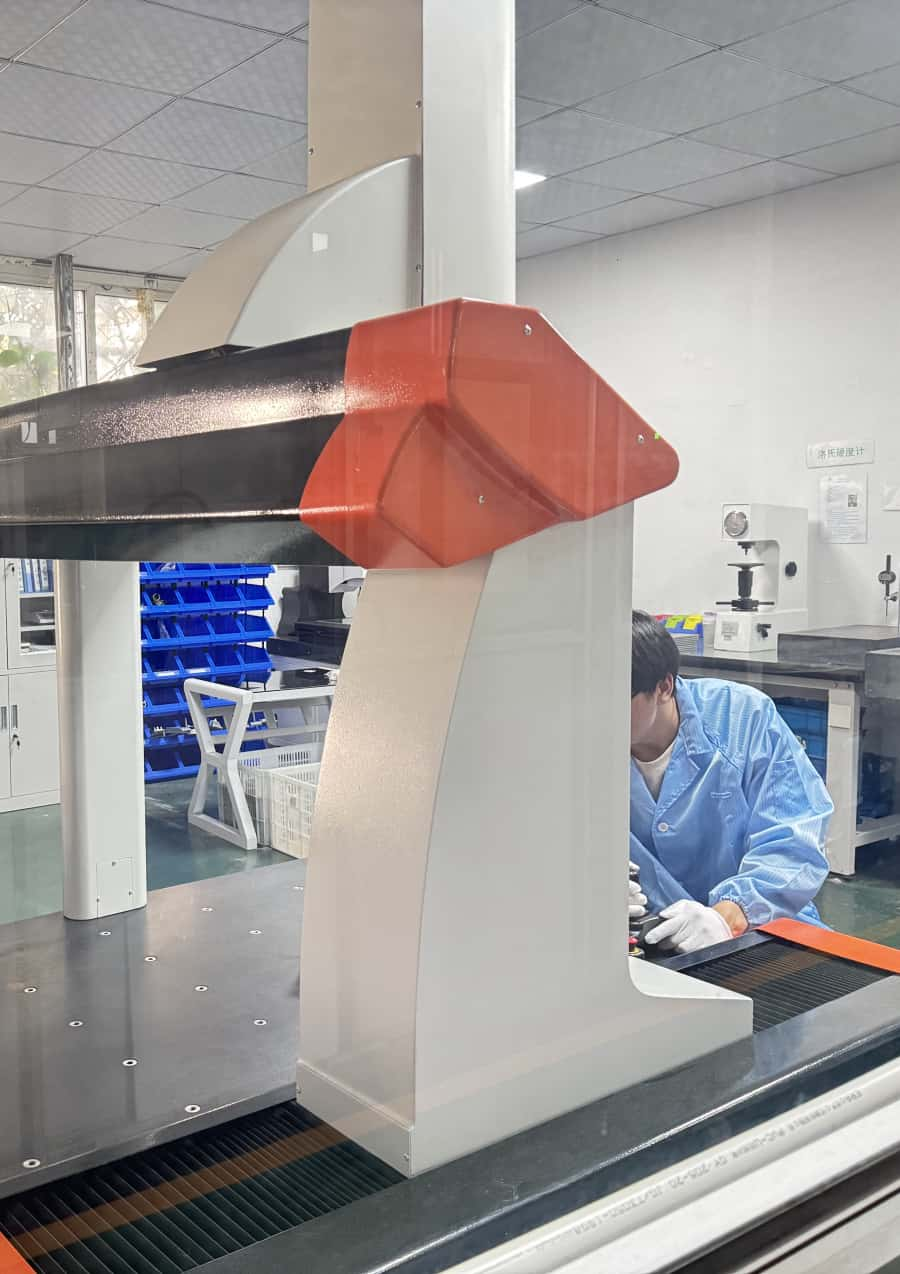

- SPC monitoring and CMM inspections for consistent precision

Common CNC Prototyping Materials

We offer a broad selection of metals and plastics for CNC machining.

All materials can be sourced with RoHS, REACH, or UL compliance upon request.

- Alloy Steel

- Tool steel

- Carbon Steel

- Titanium

- ABS

- POM(Acetal)

- EVA

- Nylon (PA)

- HDPE

- LCP

- LDPE

- LLDPE

- ETPU

- PBT

- PC (Polycarbonate)

- PC/ABS

- PEEK

- PEI

- PET

- PMMA (Acrylic)

- PP (Polypropylene)

- PVC

- Bakelite

- Ceramics

- Composites

Looking for something not listed?

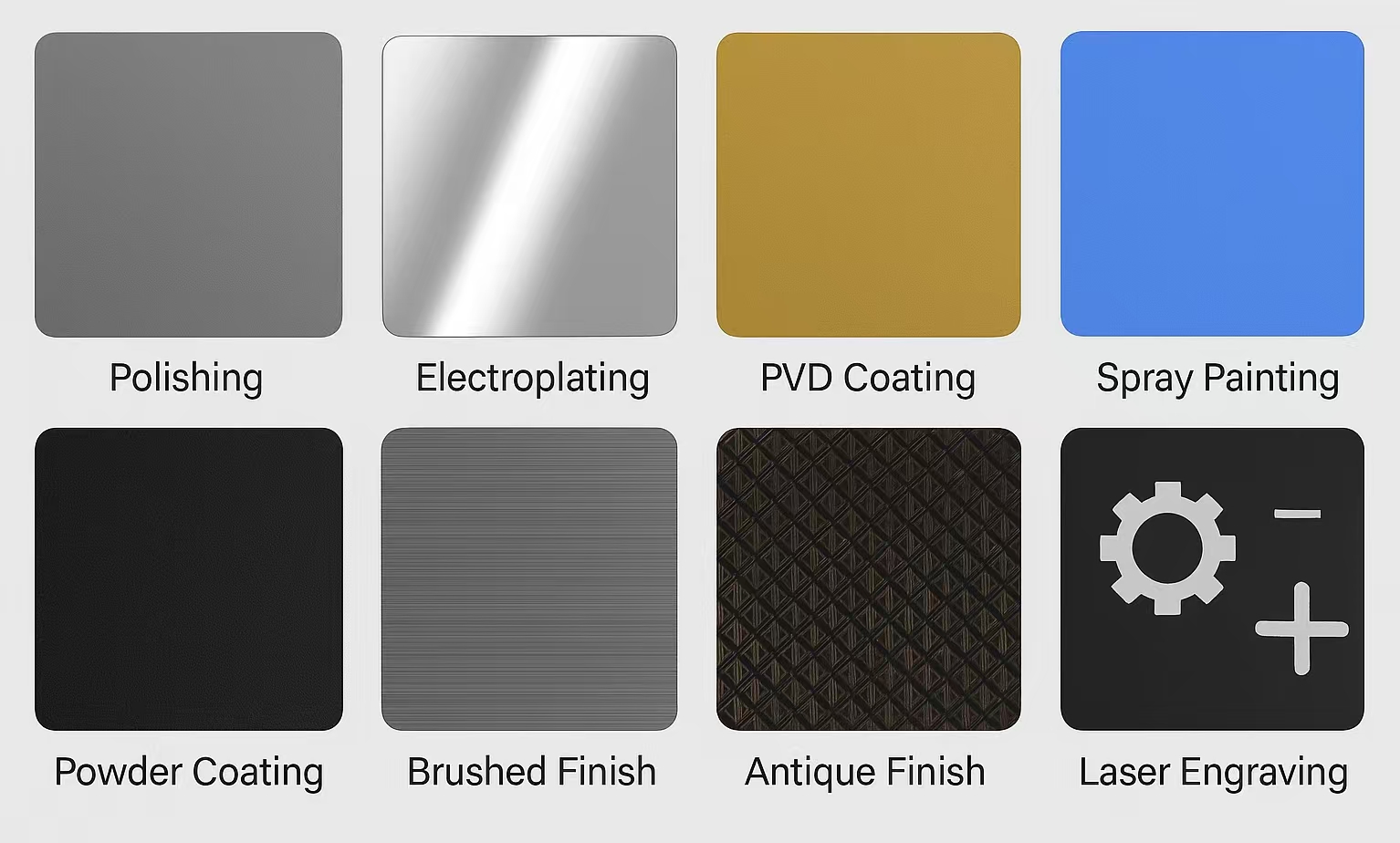

Surface Finishing Options

We offer a wide range of finishing solutions to enhance functionality, durability, and aesthetics:

- Polishing

- Spray Painting

- Screen Printing

- Laser Engraving

- Hot Stamping

- Vacuum Metallization

- Mold Texturing (Etching)

- Sandblasting

- UV Coating

- Pad Printing

- Electroplating on Plastics

Ready to elevate your aluminum castings with precision surface finishes?

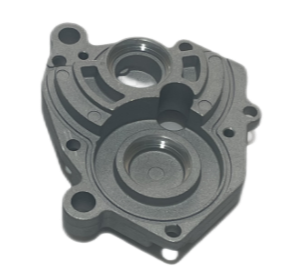

Applications & Case Studies

CNC prototyping parts are used in a wide variety of high-performance applications:

- Automotive

- Electronics

- Consumer Products

- Industrial Equipment

- New Energy Solutions

- Construction Hardware

Looking for a trusted partner for your CNC prototyping project?

Why Choose Us

20+ years of manufacturing experience

Advanced machines & strict quality control

ISO 9001 & IATF 16949

Design to finished product

Compliant with RoHS & REACH

Dedicated project tracking and global delivery

Ready to work with a reliable CNC prototyping partner?

FAQ – Frequently Asked Questions

Q: Do you offer design assistance for CNC prototyping?

A: Yes, our engineers provide DFM (Design for Manufacturability) feedback to optimize your designs for CNC machining.

Q: What is your typical lead time for CNC prototypes?

A: Most prototypes are delivered within 3–7 days, depending on part complexity.

Q: What tolerances can you achieve with CNC machining?

A: We offer tight tolerances down to ±0.01 mm for precision-critical parts.

Q: Can you work with both metals and plastics?

A: Yes, we machine a wide range of materials including aluminum, stainless steel, brass, titanium, POM, ABS, and PEEK.

Q: Is there a minimum order quantity for CNC prototyping?

A: No, we support one-off prototypes as well as low-volume production runs.

Q: Do you provide finishing services for CNC prototypes?

A: Absolutely. We offer anodizing, powder coating, bead blasting, polishing, and more.

Q: Can I send you a STEP or IGES file directly for a quote?

A: Yes, we accept STEP, IGES, STL, and other common CAD file formats.

Q: Are your CNC prototypes suitable for functional testing?

A: Yes, our prototypes use production-grade materials to ensure they perform like end-use parts.

Q: Do you ship internationally?

A: Yes, we deliver CNC prototypes worldwide with full logistics support.

Recent Blog Posts

需要添加几篇文章这里再引用