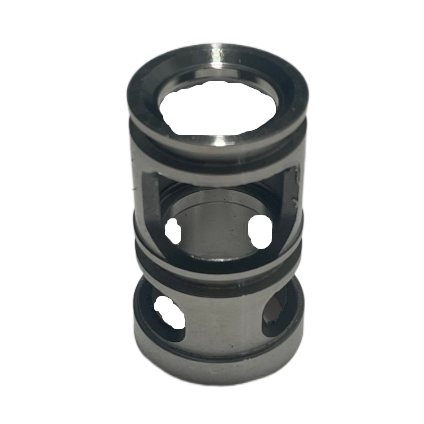

Precision CNC Turning Services for Custom Metal & Plastic Parts

Accurate, repeatable, and efficient machining of round and cylindrical components.

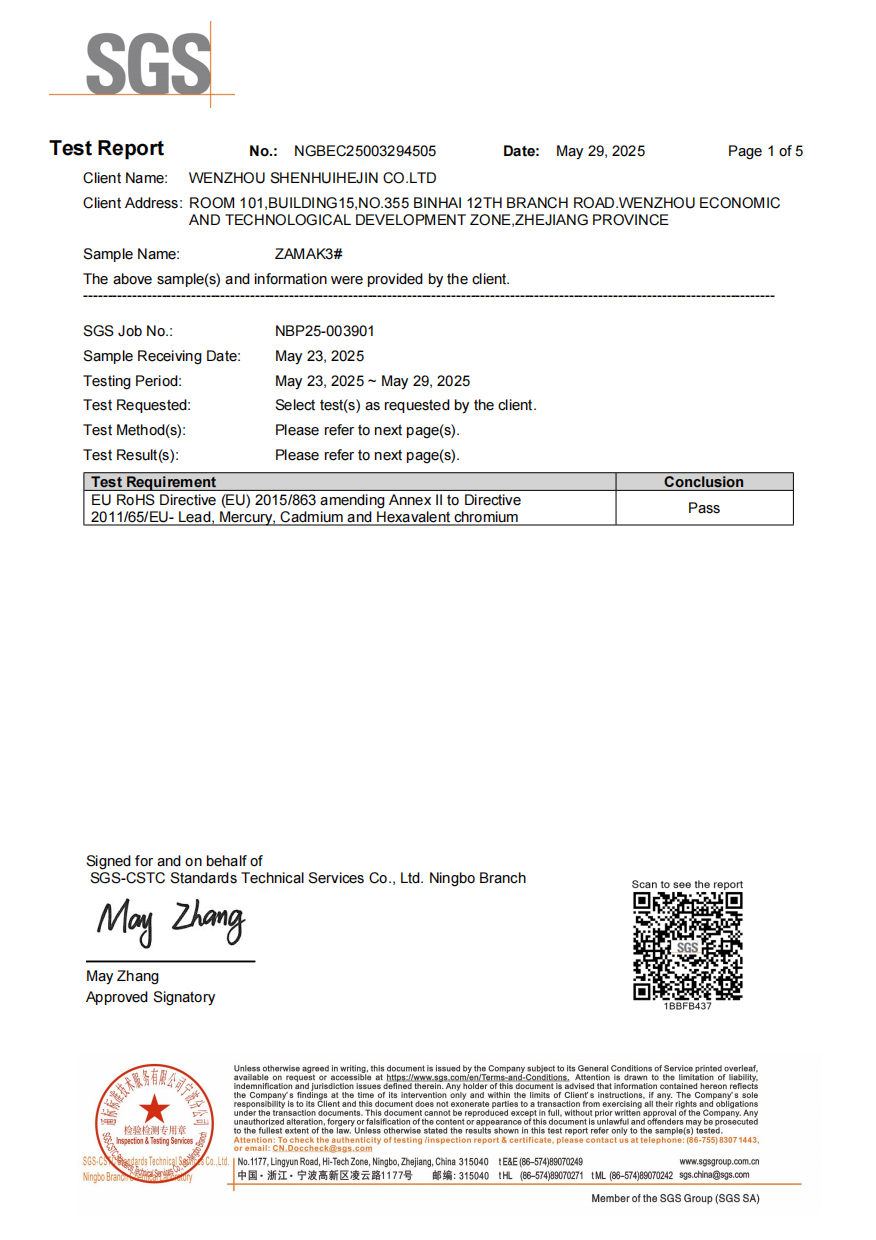

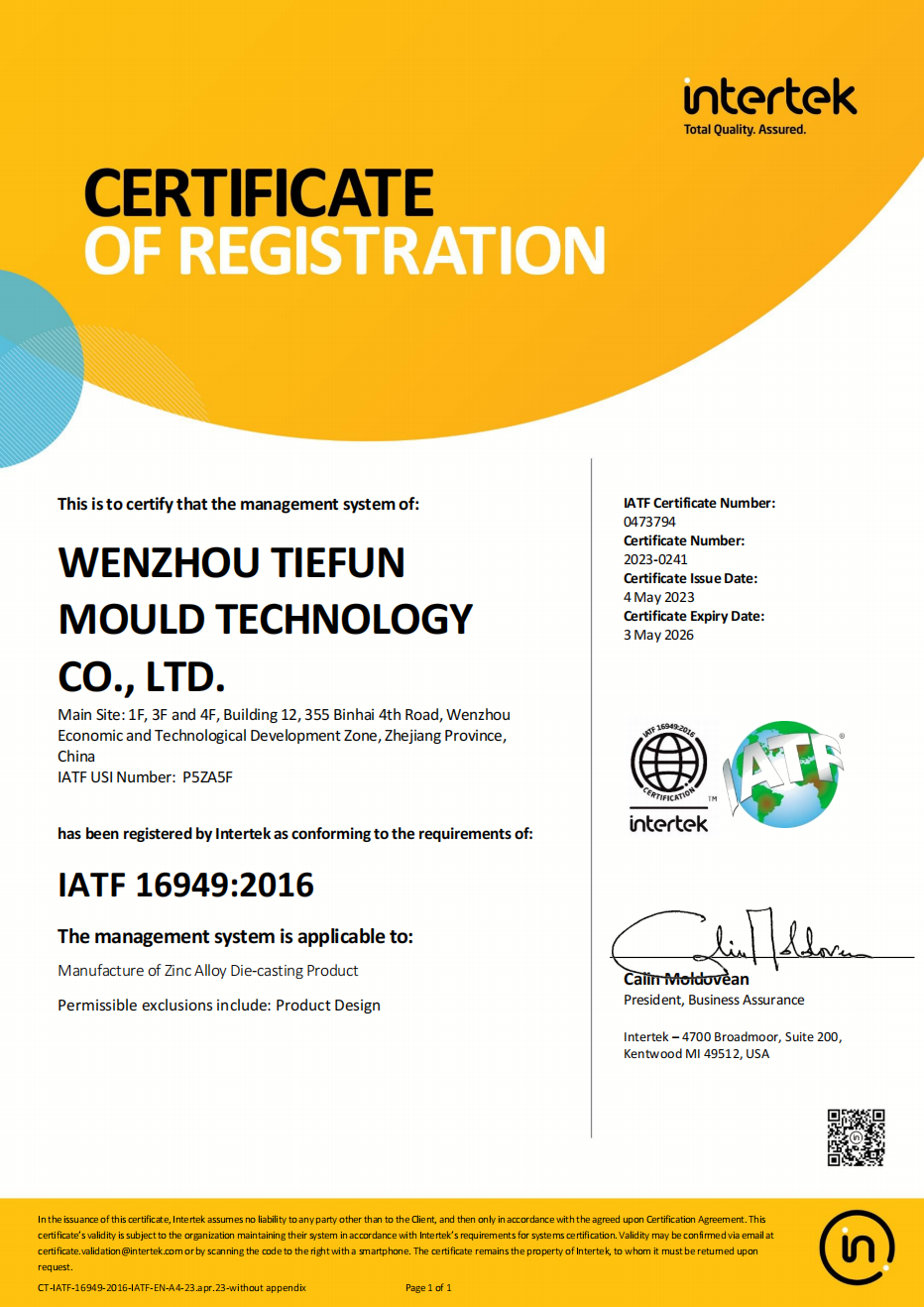

- Certifications ISO 9001:2015 | IATF 16949

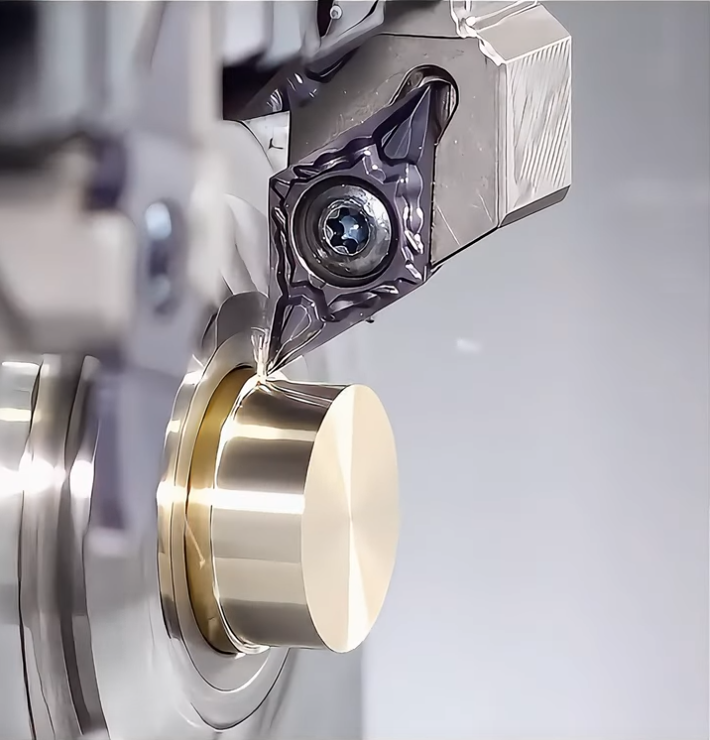

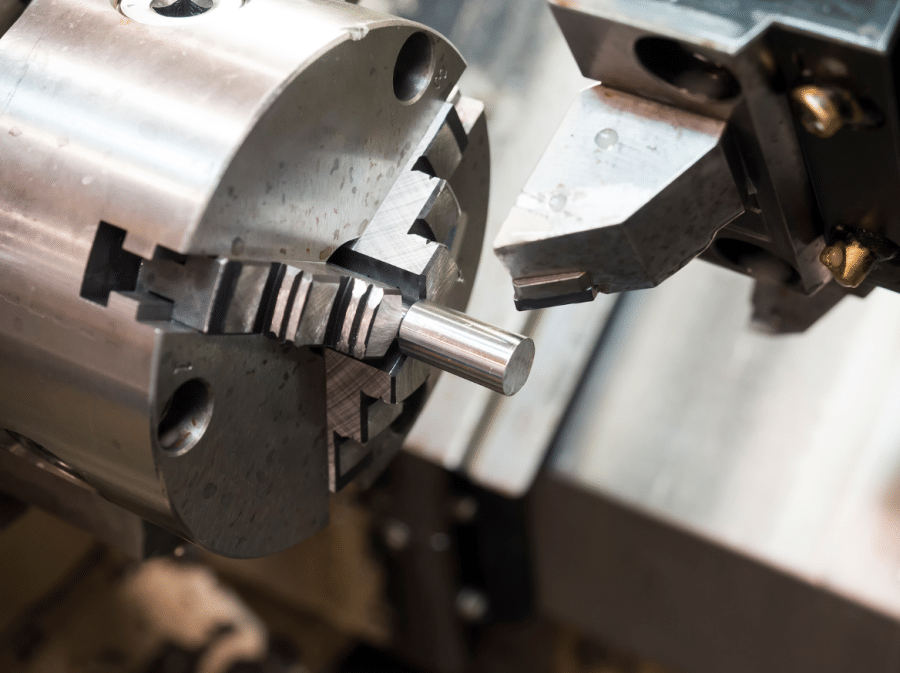

What is CNC Turning?

CNC turning is a precision machining process where a rotating workpiece is shaped by cutting tools to create cylindrical parts with tight tolerances.

How it works

The workpiece spins in a chuck while a fixed tool moves along set paths, precisely removing material as programmed by the CNC system.

Key advantages

High precision, excellent surface finish, fast production, and cost-effective machining for cylindrical parts.

Our CNC Milling Services & Capabilities

- 40+ CNC horizontal lathes for high-precision turning

- In-house turning with integrated drilling, tapping, and surface finishing

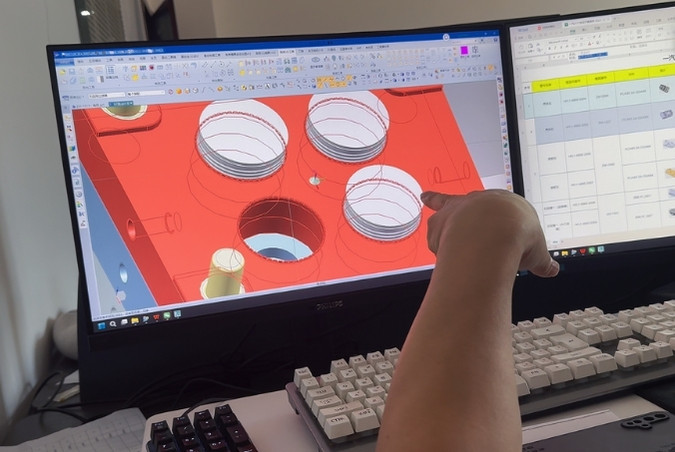

- Advanced CAD/CAM and simulation tools for optimized workflows

- Custom mold solutions for complex parts and high volumes

- 20+ years of engineering expertise

- Full DFM analysis to ensure cost-effective, high-quality production

- Tolerances: ±0.01 mm post-machining

- Batch Sizes: From prototypes to high-volume production

- Applications: Automotive, Industrial, Electronics, Energy

- ISO 9001:2015 & IATF 16949 certified

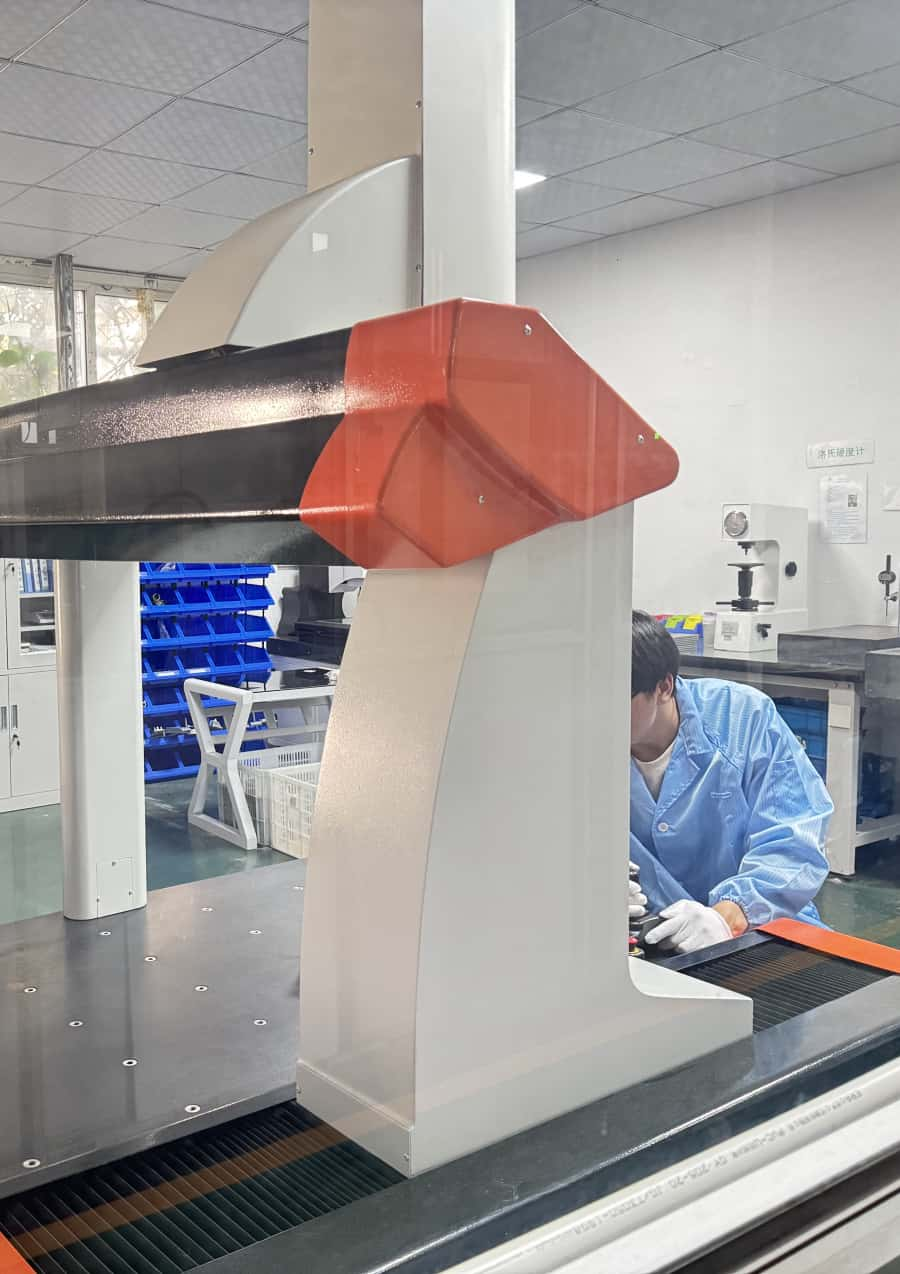

- SPC monitoring and CMM inspections for consistent precision

Common CNC Machining Materials

We offer a broad selection of metals and plastics for CNC machining.

All materials can be sourced with RoHS, REACH, or UL compliance upon request.

- Alloy Steel

- Tool steel

- Carbon Steel

- Titanium

- ABS

- POM(Acetal)

- EVA

- Nylon (PA)

- HDPE

- LCP

- LDPE

- LLDPE

- ETPU

- PBT

- PC (Polycarbonate)

- PC/ABS

- PEEK

- PEI

- PET

- PMMA (Acrylic)

- PP (Polypropylene)

- PVC

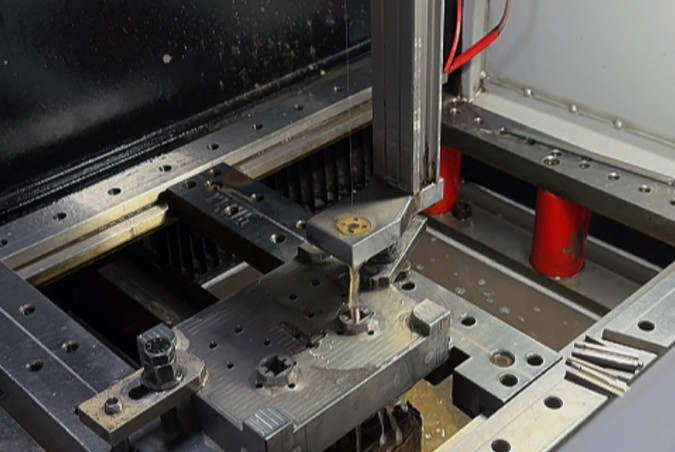

Types of CNC Turning Operations

In addition to producing basic cylindrical forms, CNC Turning supports advanced techniques for functional and aesthetic purposes:

- External Turning

- Boring (Internal Turning)

- Grooving

- Taper Turning

- Drilling

- Facing

- Parting (Cut-Off)

- Knurling

- Threading

Applications of CNC-turned Parts

CNC-turned parts are widely used across industries requiring strength, precision, and repeatability.

- Automotive

- Electronics

- Consumer Products

- Industrial Equipment

- New Energy Solutions

- Construction Hardware

Looking for a reliable expert in precision CNC turning?

Why Choose Us

20+ years of manufacturing experience

Advanced machines & strict quality control

ISO 9001 & IATF 16949

Design to finished product

Compliant with RoHS & REACH

Dedicated project tracking and global delivery

FAQ – Frequently Asked Questions

Q1: What is the typical lead time for CNC-turned parts?

A:Lead time varies by complexity and quantity, but standard turnaround is 7–15 days for most orders.

Q2: Can you handle both prototyping and mass production?

A:Yes, we support one-off prototypes, small batches, and high-volume production with consistent quality.

Q3: What file formats do you accept for CNC turning projects?

A:We accept STEP, STP, IGES, IGS, DXF, and DWG formats. 3D CAD files are preferred.

Q4: Do you offer design support or manufacturability review (DFM)?

A:Yes, our engineers can review your drawings and suggest optimizations for cost, precision, and efficiency.

Q5: Can you handle complex geometries or multi-axis turning?

A:Yes, we offer advanced CNC lathes with live tooling and Y-axis capabilities for complex parts.

Q6: Are secondary operations like threading or knurling available?

A:Absolutely. We offer a full range of CNC turning operations including threading, knurling, drilling, and parting.

Q7: What is the maximum size of a part you can turn?

A:We can handle parts up to 400 mm in diameter and 1200 mm in length. Please contact us for specific size inquiries.

Q8: Do you provide surface finishing for turned parts?

A:Yes. Options include anodizing, plating, polishing, passivation, black oxide, and more.

Q9: What materials can you source if not in stock?

A:We can custom source RoHS/REACH-compliant metals and engineering plastics per customer request.

Q10: How is quality ensured during production?

A:We perform in-process and final inspections using CMM, calipers, and SPC monitoring under ISO-certified protocols.

Q11: Can you deliver globally?

A:Yes, we ship worldwide using trusted logistics partners and can assist with documentation and customs if needed.

Q12: How do I request a quote?

A:Simply upload your CAD file and project details via our [Request a Quote] form or contact our team directly.

Recent Blog Posts

需要添加几篇文章这里再引用