Precision CNC Milling Services for Custom Metal & Plastic Parts

High-precision machined parts delivered with speed, accuracy, and consistency across any volume

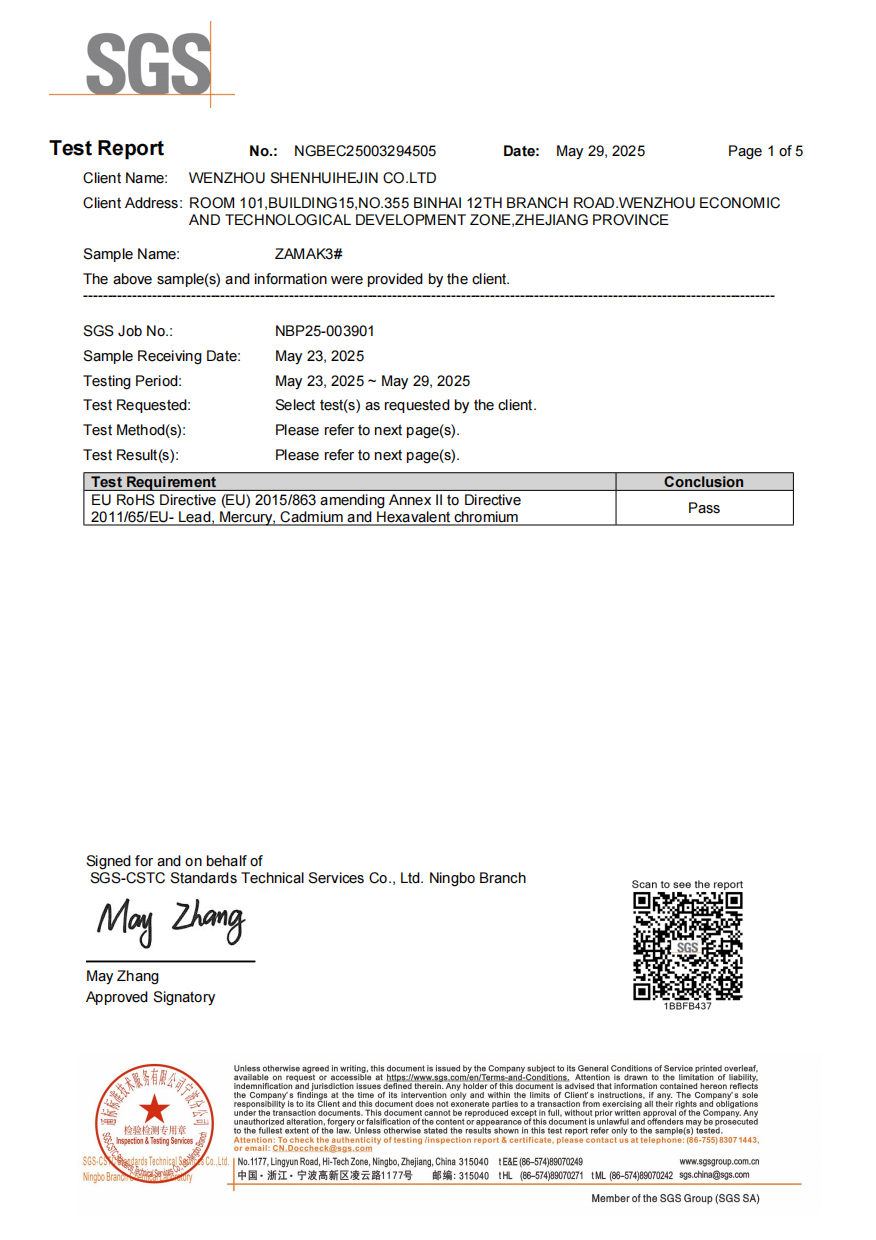

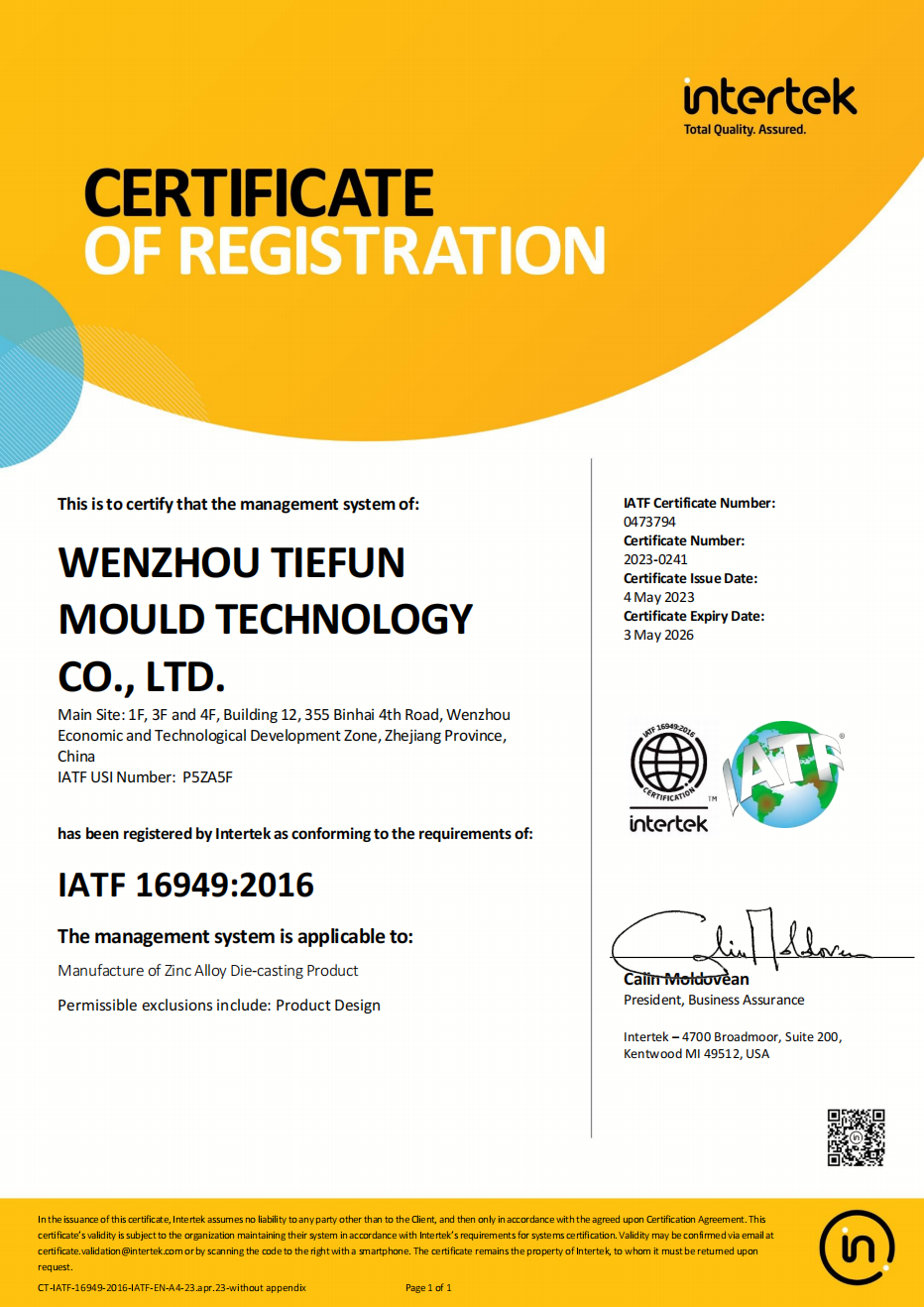

- Certifications ISO 9001:2015 | IATF 16949

What is CNC Milling?

CNC milling is a precision manufacturing process that uses computer-controlled rotary cutters to remove material and create complex parts from metal or plastic.

How It Works

CNC milling works by using computer-controlled rotary cutters to precisely remove material from a solid block, creating accurate and complex parts.

Key advantages

High precision, tight tolerances, material versatility, and cost-effective production for complex parts.

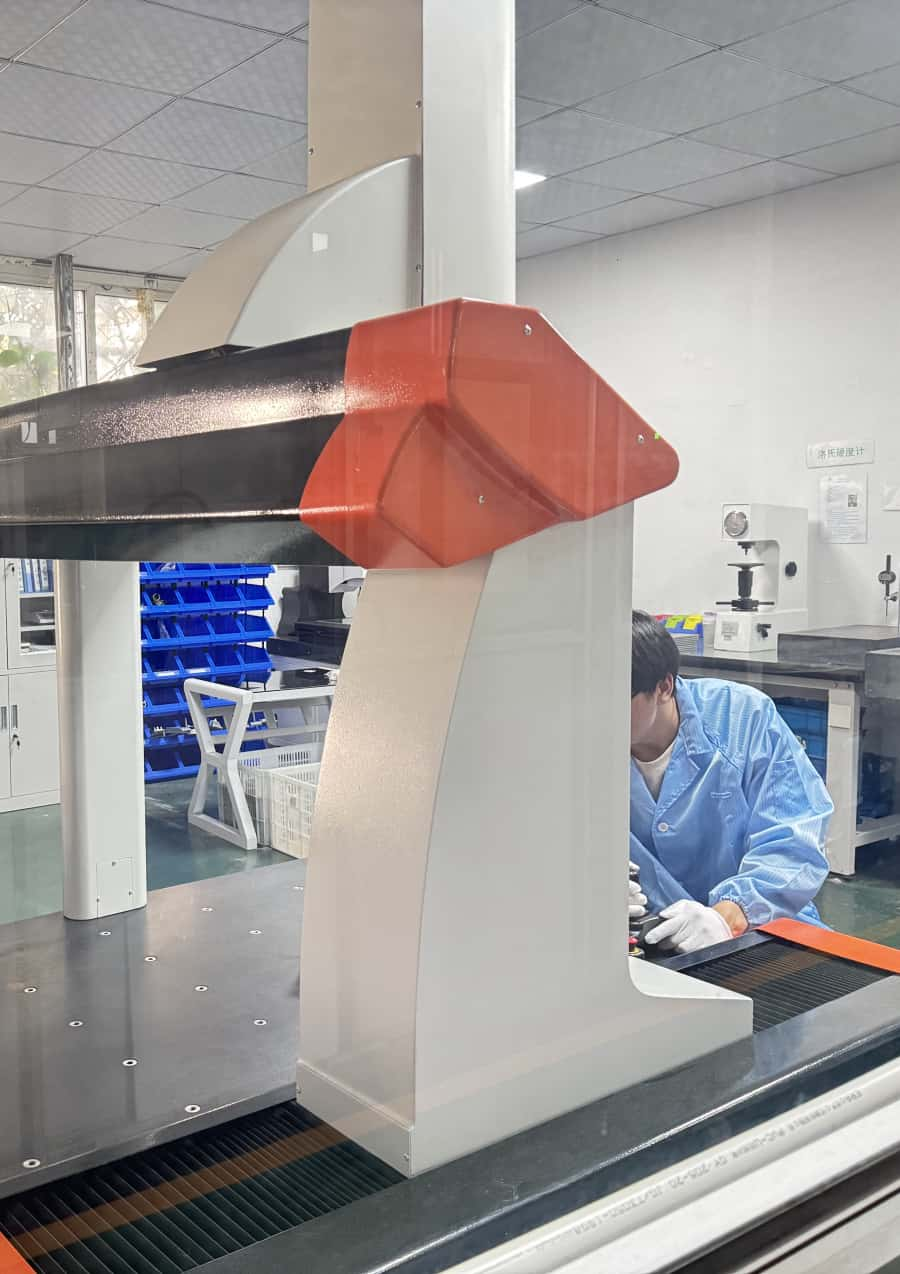

Our CNC Milling Services & Capabilities

- Custom mold solutions for complex parts and high volumes

- 20+ years of engineering expertise

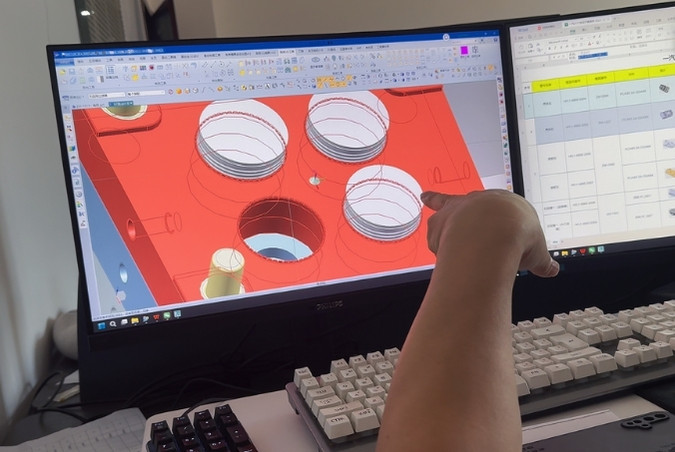

- Full DFM analysis to ensure cost-effective, high-quality production

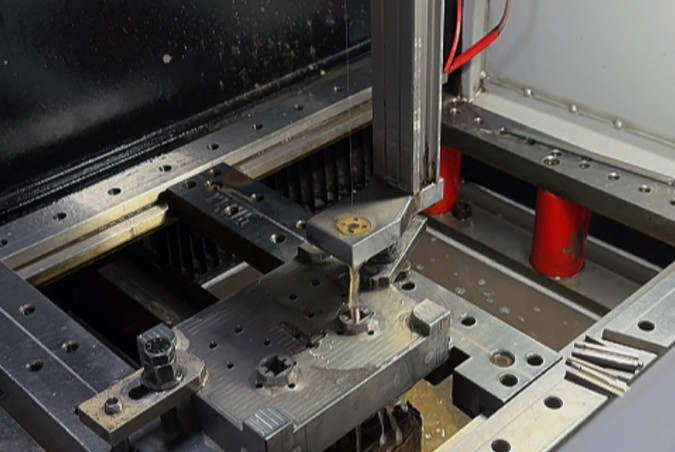

- 10+ CNC milling machines (3- and 4-axis) for precision machining

- In-house CNC machining center

- CAD/CAM & Moldflow simulation for optimized designs

- Tolerances: ±0.01 mm post-machining

- Batch Sizes: From prototypes to high-volume production

- Applications: Automotive, Industrial, Electronics, Energy

- ISO 9001:2015 & IATF 16949 certified

- SPC monitoring and CMM inspections for consistent precision

Common CNC Machining Materials

We offer a broad selection of metals and plastics for CNC machining.

All materials can be sourced with RoHS, REACH, or UL compliance upon request.

- Ceramics

- Tool steel

- Carbon Steel

- Titanium

- ABS

- POM(Acetal)

- EVA

- Nylon (PA)

- HDPE

- LCP

- LDPE

- LLDPE

- ETPU

- PBT

- PC (Polycarbonate)

- PC/ABS

- PEEK

- PEI

- PET

- PMMA (Acrylic)

- PP (Polypropylene)

- PVC

- Bakelite

- Ceramics

- Composites

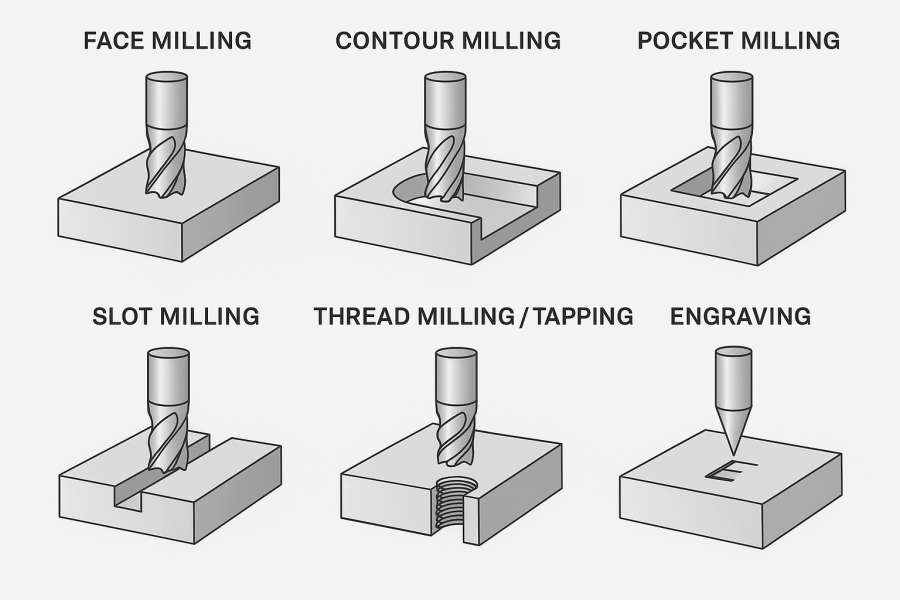

Types of CNC Milling Operations

Face Milling – Flat surface and finish cuts

Contour Milling – Complex curves and profiles

Pocket Milling – Internal cavities or cutouts

Slot Milling – Precision grooves or keyways

Thread Milling / Tapping – Threads for bolts and screws

Engraving – Surface text and logo marking

CNC Milling Applications: From Tooling to Production

Rapid Prototyping

With fast turnaround, wide material options, and cost-effective production, CNC milling efficiently delivers high-quality prototypes for functional testing and design validation.

Rapid Tooling

CNC milling is ideal for creating custom tooling such as fixtures, jigs, and low-volume molds with speed and reliability across various materials.

End-Use Production

CNC-milled parts offer tight tolerances, excellent surface finish, and material versatility—perfect for small to medium-volume production in automotive, aerospace, medical, and electronics industries.

Applications in Multiple Industries

Empowering your success with advanced, high-quality solutions for every industry.

Why Choose Us

20+ years of manufacturing experience

Advanced machines & strict quality control

ISO 9001 & IATF 16949

Design to finished product

Compliant with RoHS & REACH

Dedicated project tracking and global delivery

FAQ – Frequently Asked Questions

Q1: Can CNC milling process both metal and plastic parts?

A: Yes. It works with metals (aluminum, brass, steel) and engineering plastics (POM, ABS, PC) at high precision.

Q2: What’s the difference between 3-axis and 4-axis milling?

A: 3-axis handles flat, simple shapes. 4-axis allows multi-surface machining without repositioning.

Q3: Why choose CNC milling over 3D printing?

A: CNC milling delivers stronger parts, tighter tolerances, and superior surface finishes – perfect for functional end-use components.

Q4: Can I send a physical sample instead of CAD files?

A: Yes. We can reverse-engineer samples with 3D scanning or manual measurements.

Q5: What factors affect CNC milling costs?

A: Material, complexity, tolerances, surface finish, and quantity. We also suggest cost-saving options at quotation.

Q6: Can you handle assemblies with multiple materials?

A: Yes. We machine parts in different materials and can assist with secondary assembly.

Q7: What tolerances can you achieve?

A: Typical: ±0.01 mm for critical features. Tighter tolerances depend on geometry and material.

Q8: Do you support threads and inserts?

A: Absolutely. We offer thread milling, tapping, and insert installation (Heli-Coils, brass inserts).

Q9: How is part quality ensured?

A: 100% dimensional checks, SPC monitoring, and detailed reports (CMM, roughness, PPAP) on request.

Q10: Can you help redesign parts for CNC?

A: Yes. Our engineers provide DFM feedback for better machinability and cost savings.

Q11: Do you have a minimum order quantity?

A: No MOQ. We support prototypes and production runs of any size.

Q12: Do you ship internationally?

A: Yes. We deliver worldwide (U.S., EU, Middle East, Southeast Asia) with EXW, FOB, CIF, or DDP terms.

Recent Blog Posts

需要添加几篇文章这里再引用