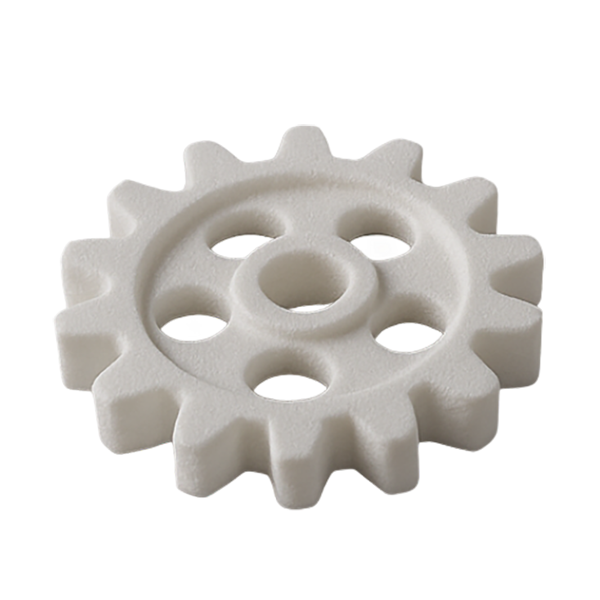

High-Precision SLS 3D Printing Services for Rapid Prototyping

Achieve Unmatched Detail with Industrial-Grade SLS 3D Printing

— Where Complexity Meets Precision

— Redefine Prototyping with SLS Precision

What is Selective laser sintering (SLS) ?

Selective Laser Sintering (SLS) is an advanced additive manufacturing (3D printing) technology that uses a high-powered laser to fuse powdered materials—typically nylon (PA), TPU, or other thermoplastics—into solid, functional 3D objects.

How does SLS 3D Printing work

SLS Working principle of SLS is to use a high-power laser to selectively fuse thermoplastic powder layer by layer, gradually building a solid part from a digital 3D model.

Key advantages

SLS Advantages:SLS offers high design freedom, strong functional parts, and No Support structures, making it ideal for complex, end-use 3D printing applications.

Applications of SLS

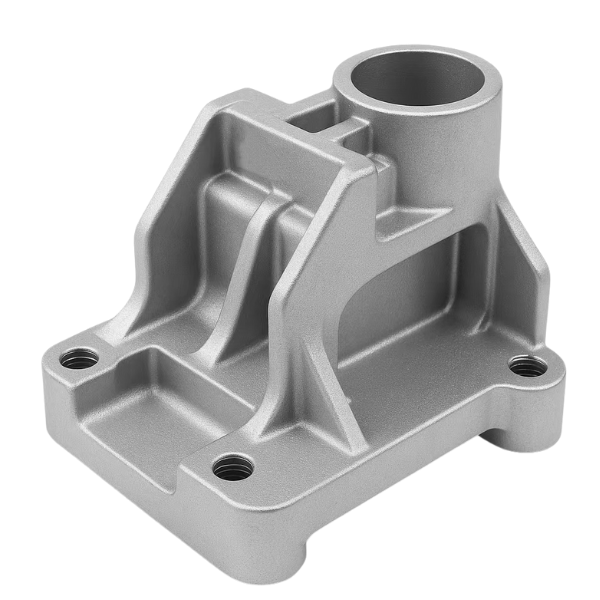

SLS is widely used for producing functional prototypes, end-use parts, and complex geometries in industries such as automotive, aerospace, medical, and consumer products.

Automotive: brackets, housings, ducts

Aerospace: lightweight structural parts

Medical: prosthetics, orthotics

Industrial: functional prototypes, tooling

Consumer: wearables, eyewear frames

3D Printing Spec

Get this quick reference to learn about materials, finishes, considerations and technology options for our 3D printing technologies.3D Printing.xlsx

Our Capabilities with SLS 3D Printing

With a stable SLS production line and a professional engineering team, we support rapid prototyping and small to medium batch production, significantly reducing the time from design to finished part.

Our SLS process delivers dimensional accuracy within ±0.1 mm, ensuring crisp detail and meeting the needs of high-tolerance industrial components and appearance parts.

Using imported nylon materials such as PA12 and PA11, our parts feature excellent mechanical strength, heat resistance, and impact durability—suitable for direct functional use.

We offer black, white, and gray nylon, glass-filled composites, and flexible TPU to meet varying industry-specific and functional requirements.

From sandblasting, dyeing, and painting to surface finishing, we enhance both aesthetics and performance for display-grade and consumer-ready products.

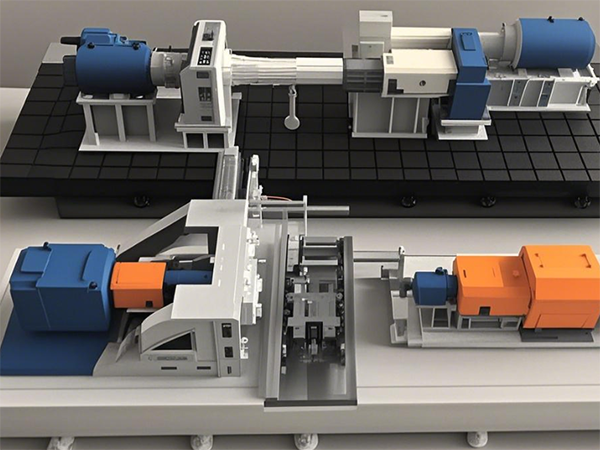

Exhibition Snapshot - Shared with Client's Approval (3D Printing)

Our 3D printing has helped clients cut design iteration time by up to 50%, enabling faster product launches and timely trade show presentations.

Why Choose Us

20+ years of manufacturing experience

Advanced machines & strict quality control

ISO 9001 & IATF 16949

Design to finished product

Compliant with RoHS & REACH

Dedicated project tracking and global delivery

Printable Materials for SLS 3D Printing

| Material | Black nylon PA12 |

| Picture |

|

| Heat Deflection Temperature(0.46MPa) | 173℃ |

| Minimum wall thickness | 0.5mm |

| Minimum aperture | 1.2mm |

| Material hardness(Shore D) | 86 |

| Tensile strength (tensile) | 50MPa |

| Tensile strength (break) | 70MPa |

| Bending Strength | 75-80MPa |

| Flexural modulus | 2800MPa |

| Print layer height | 0.1mm |

| Printing error | 2.5‰ |

| Water absorption | Non |

| Impact strength | 2.7KJ/M |

Surface Finish Options for SLS 3D Printing

SLS parts naturally have a slightly matte and grainy texture due to the sintered powder. To enhance aesthetics and performance, we offer a range of surface finishing options tailored to your application:

Slightly rough, powdery surface Suitable for internal components or functional parts No additional processing — fastest lead time

Removes loose powder and smooths surface texture Uniform matte finish Ideal for prototypes and assembly-ready components

Adds rich, uniform color (typically black, gray, red, blue) Maintains part detail while improving appearance UV- and wear-resistant options available

Enhances smoothness and visual appeal Suitable for consumer-facing products Best used on parts with accessible surfaces

Reduces porosity and increases resistance to moisture and chemicals Improves cleanliness and wipeability Optional gloss or matte finishes available

Enables color customization and branding Can simulate injection-molded finishes Supports both aesthetic and functional coatings (e.g., UV-resistant)

Important Notes for 3D Printing

Minimum Wall Thickness:

- Recommended minimum wall thickness for plastic/resin parts: ≥ 0.8 mm;

- Recommended minimum wall thickness for metal parts (SLM): ≥ 0.3–0.5 mm;

- Walls thinner than recommended might fail during printing or deform easily. Please confirm in advance.

To ensure smooth processing for mold design and manufacturing, please kindly follow these guidelines when exporting and submitting STL files:

- Triangle Face Normals

Please make sure that the normals of all triangle faces are correctly oriented — the front and back faces should not be reversed. All face normals should point outward to define a closed, solid model. Incorrect normals may cause errors in printing or mold analysis. - No Holes or Gaps

The STL file must represent a watertight, fully closed solid. There should be no missing faces or holes in the geometry. Non-manifold edges or open surfaces may result in processing or printing failures.

If possible, please run a mesh check or repair in your modeling software before exporting the STL file.

Dimensional Accuracy and Tolerances:

- Our standard tolerance ranges are:

Resin (SLA/DLP): ±0.05–0.1 mm;

Nylon (SLS): ±0.1–0.2 mm;

Metal (SLM): ±0.1–0.2 mm;

CNC Machined Parts: ±0.1 mm - If higher precision or special tolerances are required, please clearly specify in advance.

Assembly Requirements:

- For parts requiring assembly, please provide clear assembly drawings and instructions. We will assemble and inspect the parts before shipment.

- If no assembly request or assembly drawings are provided by the customer, we will not assemble by default and will not be responsible for any resulting issues.

- Recommended assembly clearance: at least 0.15 mm per side.

Painting Color Standards:

- If painting is required, please provide a clear Pantone color code or standard color sample.

- If no color code or sample is provided, we will not be responsible for any color deviation.

Special Requirements for CNC Machined Parts:

- For CNC machined parts, please provide 2D engineering drawings clearly indicating tolerances, thread specifications, and any special machining requirements.

- Without provided 2D drawings, we will manufacture according to the supplied 3D data and standard international tolerances. Areas without special instructions will be processed according to general standards.

Additional Recommendations (For Reference):

- Small threads are recommended to be machined or inserted separately; direct 3D printing of small threads is generally not advised.

- Please inform us in advance regarding specific mechanical requirements (strength, toughness, heat resistance, etc.) to confirm suitable materials and processes.

- Long, thin, unsupported, or thin-walled structures may deform; structural optimization during the design stage is highly recommended.

to life with precise, professional-grade SLS printing?