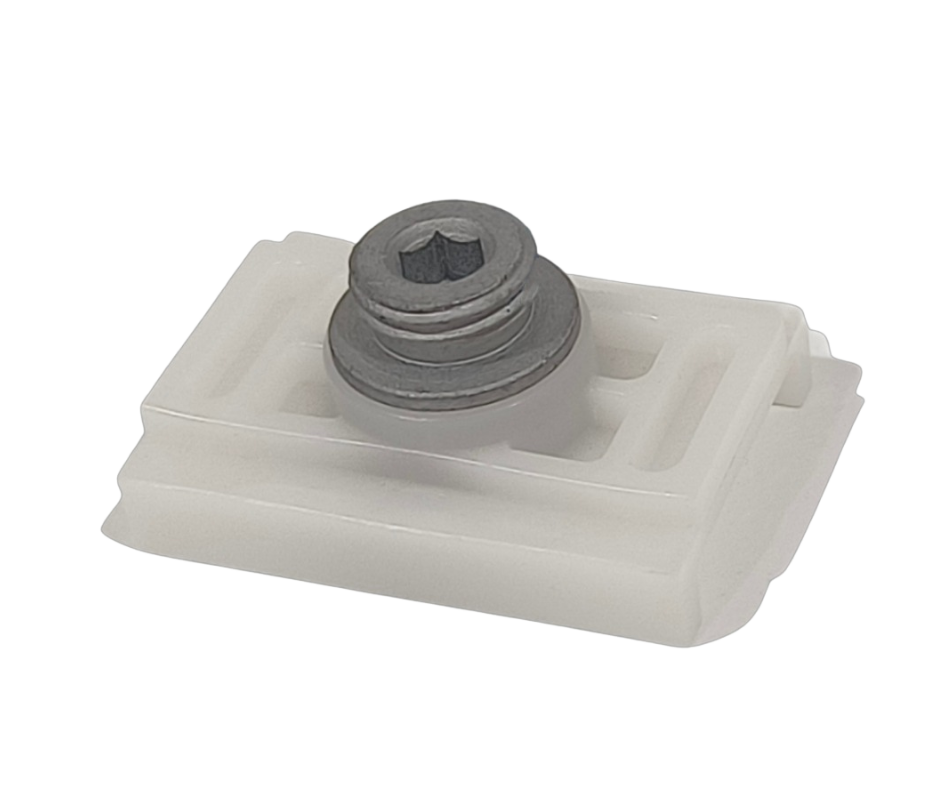

High-Precision Injection Molding Services for Custom Plastic Parts

Mass-Production Ready Injection Molding for Durable, Accurate Parts

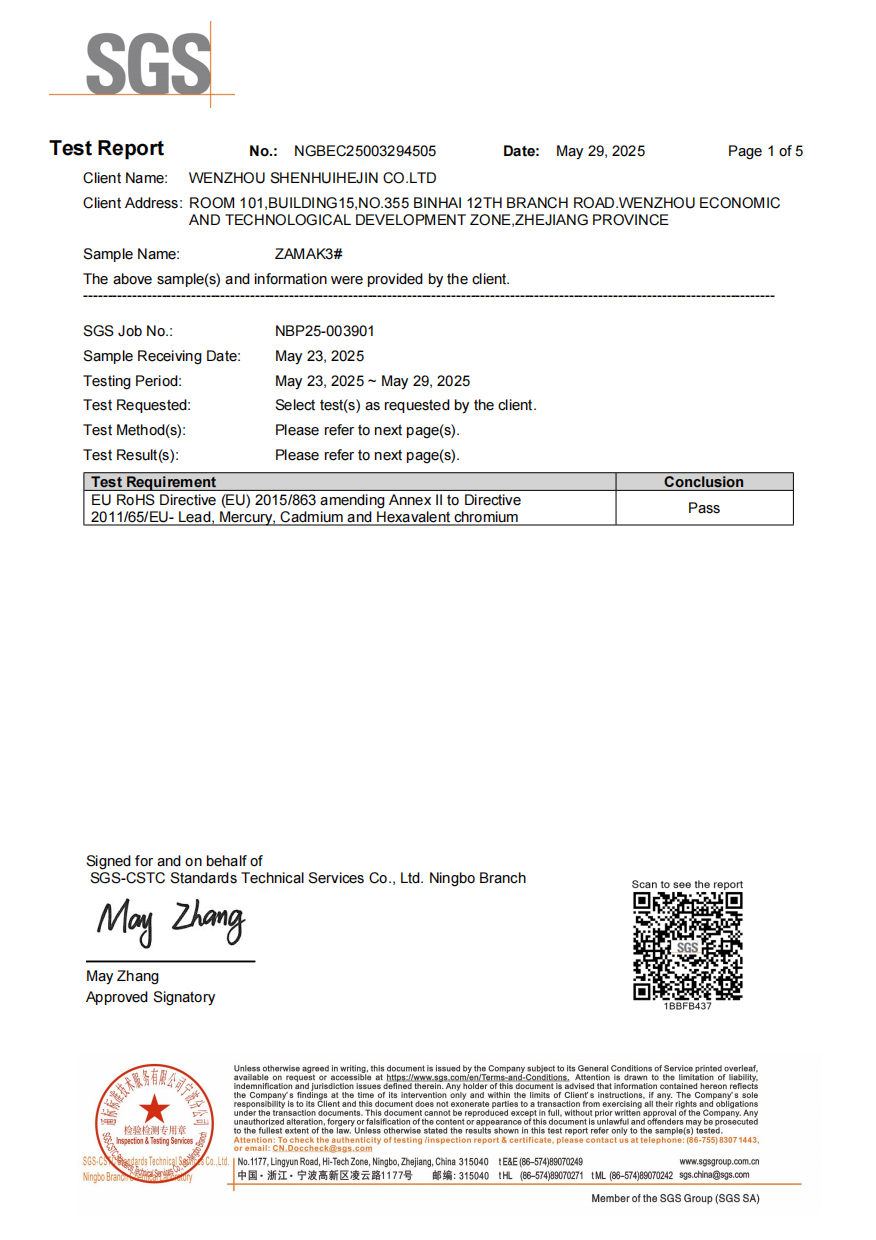

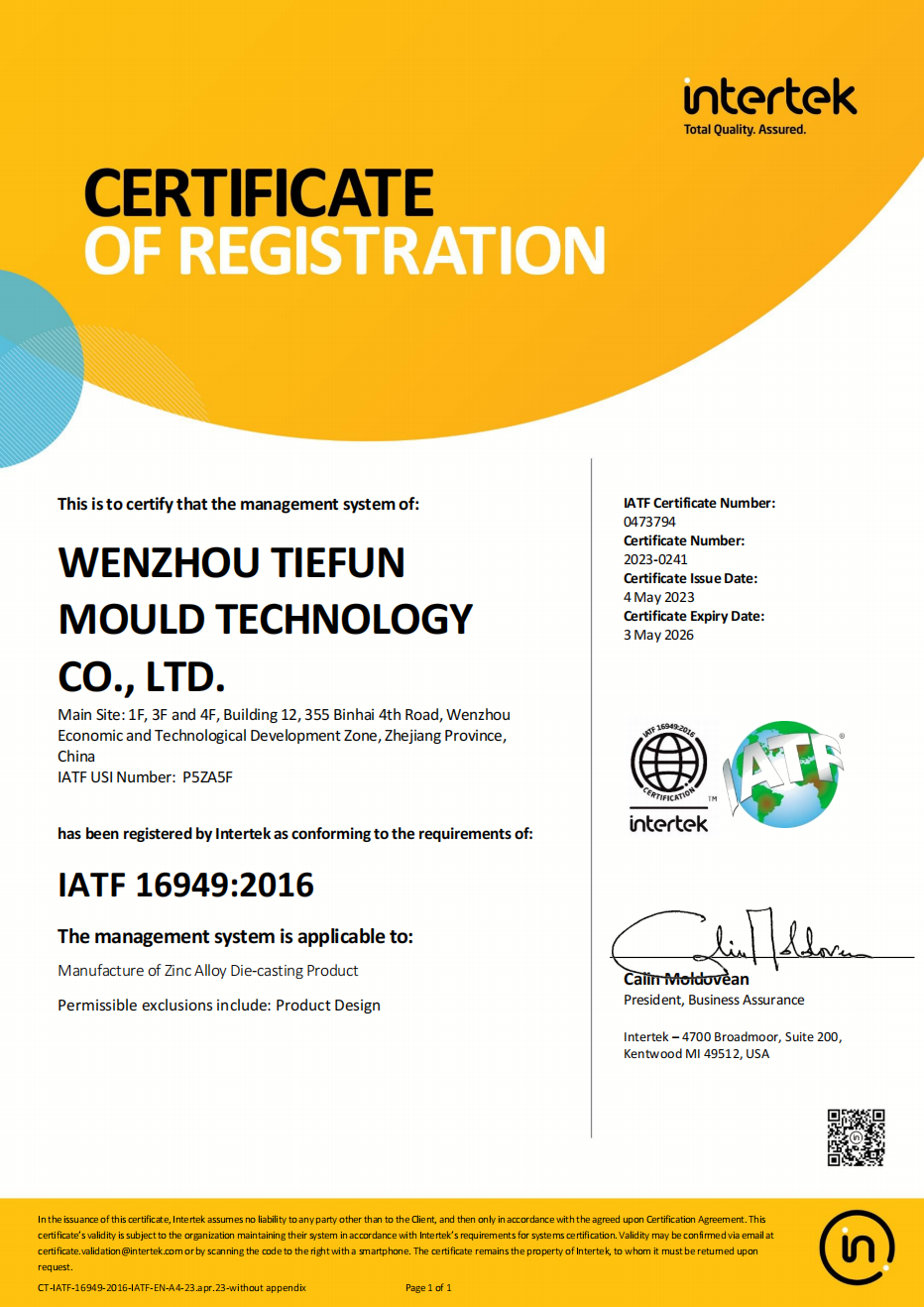

- Certifications ISO 9001:2015 | IATF 16949

What is Injection Molding?

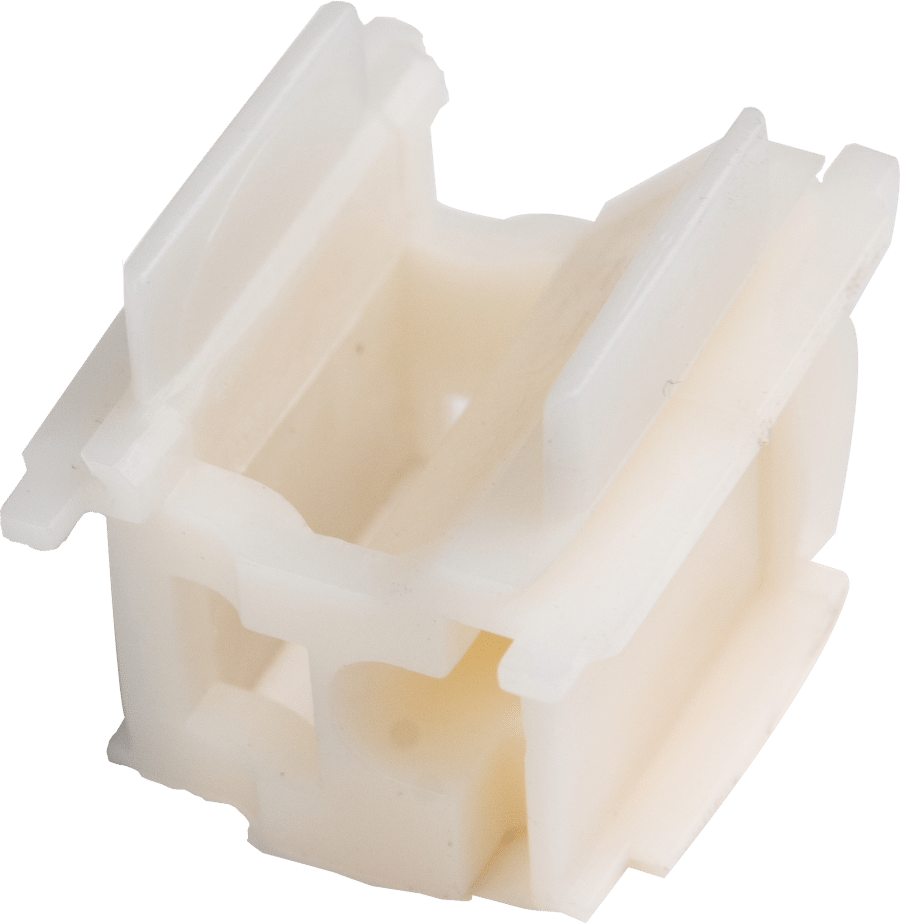

Injection molding is a precision manufacturing process used to produce plastic components by injecting molten material into a custom-designed mold.

How It Works

Molten thermoplastics like ABS or reinforced nylon are injected under high pressure into precision steel or aluminum molds. Once cooled and solidified, the mold opens and the part is ejected.

Advantages of Injection Molding:

High precision, efficiency, and repeatability—perfect for complex, high-volume parts with minimal waste.

Our Injection Molding Capabilities

- Custom mold solutions for complex parts and high volumes

- 20+ years of engineering expertise

- Full DFM analysis to ensure cost-effective, high-quality production

- 7+ Haitian Injection Molding Machines (up to 800T)

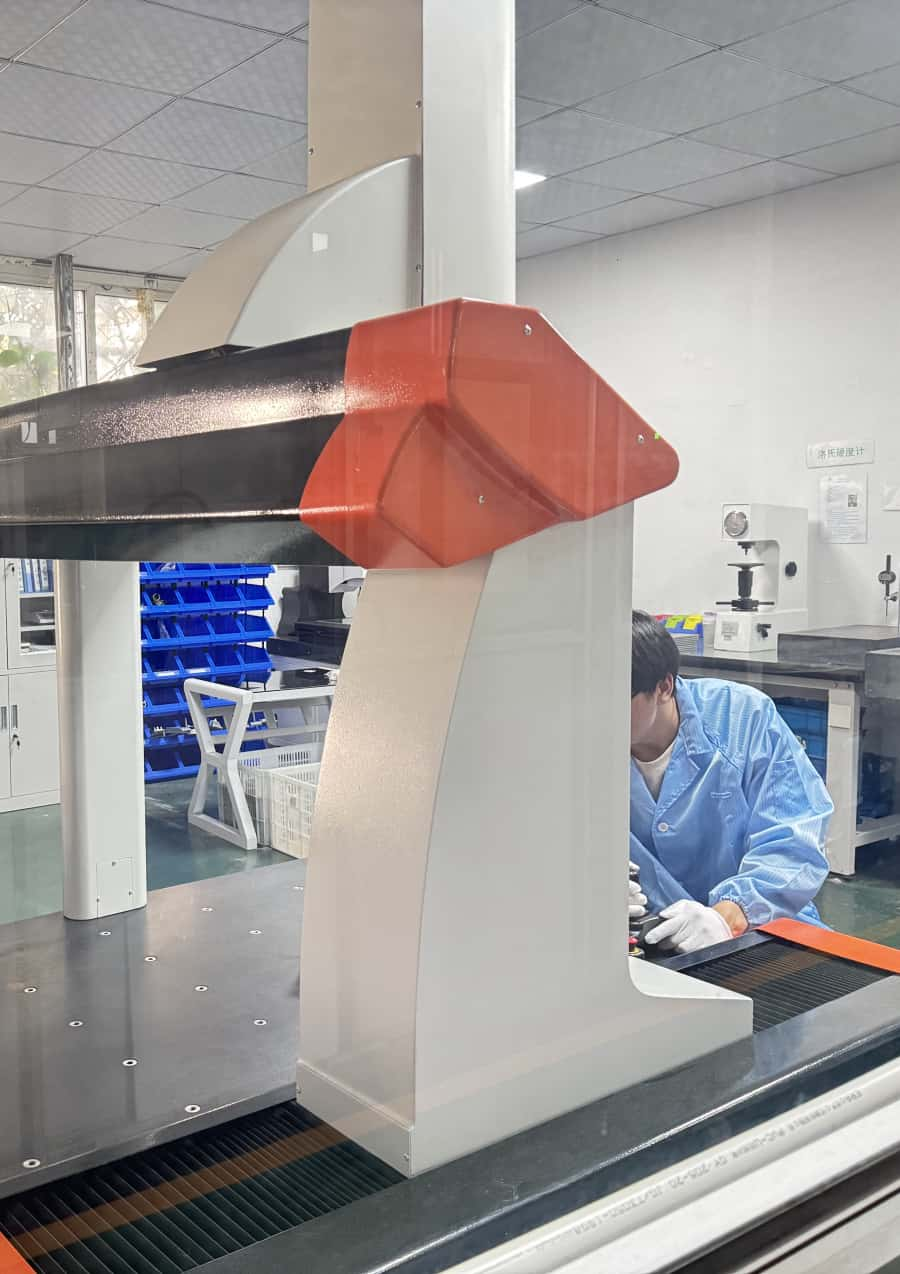

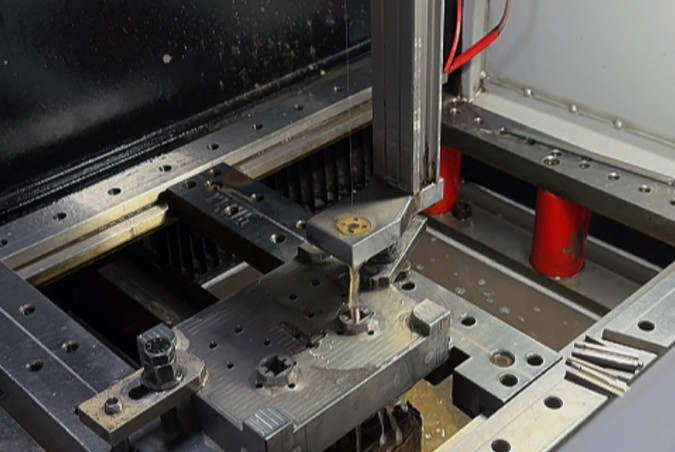

- In-house CNC machining center

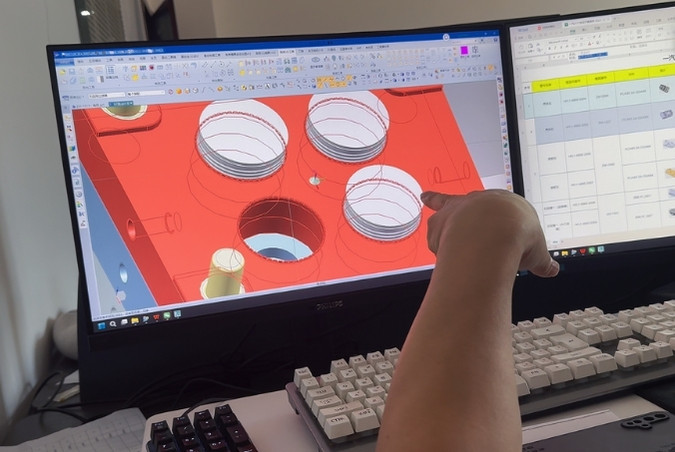

- CAD/CAM & Moldflow simulation for optimized designs

- Tolerances: ±0.01 mm post-machining

- Batch Sizes: From prototypes to high-volume production

- Applications: Automotive, Industrial, Electronics, Energy

- ISO 9001:2015 & IATF 16949 certified

- SPC monitoring and CMM inspections for consistent precision

Injection Molding Materials

We process a wide range of thermoplastics including:

- ABS

- PC/PBT

- PC (Polycarbonate)

- Acetal (Copolymer, Homopolymer/Delrin)

- PEEK

- PP (Polypropylene)

- EVA

- PE (HDPE, LDPE, LLDPE)

- PMMA

- ETPU

- PEI

- PPE/PS

- LCP

- PET

- PS

- Nylon (PA)

- PETG

- PSU

- PBT

- PMMA (Acrylic, Plexiglas)

- PU

- PC/ABS

- POM

- PVC

Not sure which material fits your part’s performance needs?

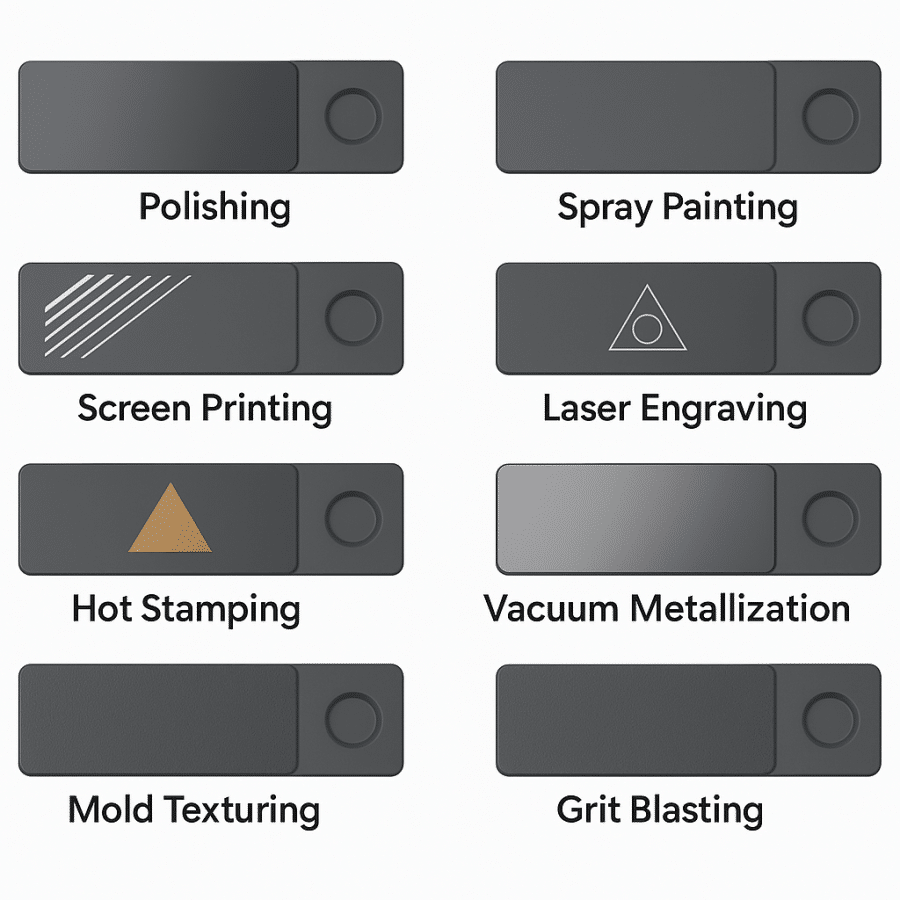

Surface Finishing Options

We offer a wide range of finishing solutions to enhance functionality, durability, and aesthetics:

Why Surface Finishing Matters?

Surface finishing enhances more than just appearance—it can improve:

- Scratch and wear resistance

- UV and chemical resistance

- Brand visibility and user experience

- Product lifespan and perceived value

Want to know which finish is right for your project?

Applications & Case Studies

Injection molding is used to produce high-quality parts across diverse industries:

- Automotive

- Electronics

- Home Appliances

- Industrial Equipment

- Consumer Products

- New Energy Solutions

- Construction Hardware

Why Choose Us

20+ years of manufacturing experience

Advanced machines & strict quality control

ISO 9001 & IATF 16949

Design to finished product

Compliant with RoHS & REACH

Dedicated project tracking and global delivery

FAQ – Frequently Asked Questions

Q1: Can you help with product design or CAD file adjustments?

A: Yes. We refine designs for better moldability and cost efficiency, with Moldflow analysis to predict material flow.

Q2: What mold finishes can you provide?

A: SPI and VDI textures from high-gloss to matte or rugged surfaces for various applications.

Q3: Can molds be shipped or transferred to us?

A: Yes. We respect mold ownership and provide shipping with full documentation.

Q4: How fast do you respond to RFQs?

A: Quotes in 24 hours; technical reviews in 1–2 working days.

Q5: Are your parts automotive compliant?

A: Yes. We follow IATF 16949 and offer PPAP, material traceability, and inspection reports.

Q6: Do you handle global shipping?

A: Yes. We support FOB, CIF, DDP terms with full customs documentation.

Q7: Do you work with international clients?

A: Yes. Over 60% of our business comes from Europe, North America, and Southeast Asia.We offer English support and video call briefings.

Q8: Can you supply compliant materials (UL94, FDA, REACH)?

A: Yes. All materials meet global standards with certifications available.

Q9: What if we need mold changes later?

A: Minor updates take 3–7 days; major changes handled via rework or inserts.

Recent Blog Posts

需要添加几篇文章这里再引用