Contract Manufacturing

Your End-to-End Partner in Metal and Plastic for OEM&ODM Production

- Certifications ISO 9001:2015 | IATF 16949

What Is Contract Manufacturing?

Contract manufacturing means outsourcing your entire production process to a trusted partner. From design support to mass production, assembly, and global delivery—we help you scale faster and reduce operational costs.

Understanding the Difference: OEM, ODM & Contract Manufacturing

OEM – You Design, We Produce

We manufacture products to your exact specifications and branding.

ODM – We Design, You Brand

We handle product design and production, allowing you to focus on sales and marketing.

Contract Manufacturing – Full-Service Partner

From design to delivery, we manage your entire production process, including assembly and logistics.

Ready to bring your designs to life at scale? Let’s make it happen.

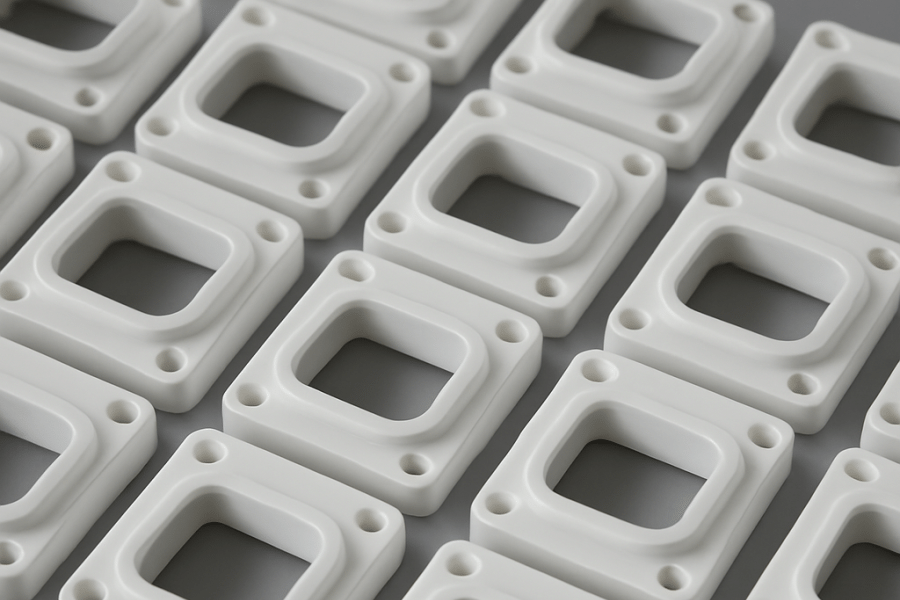

Our Contract Manufacturing Capabilities

We provide a seamless production process that covers:

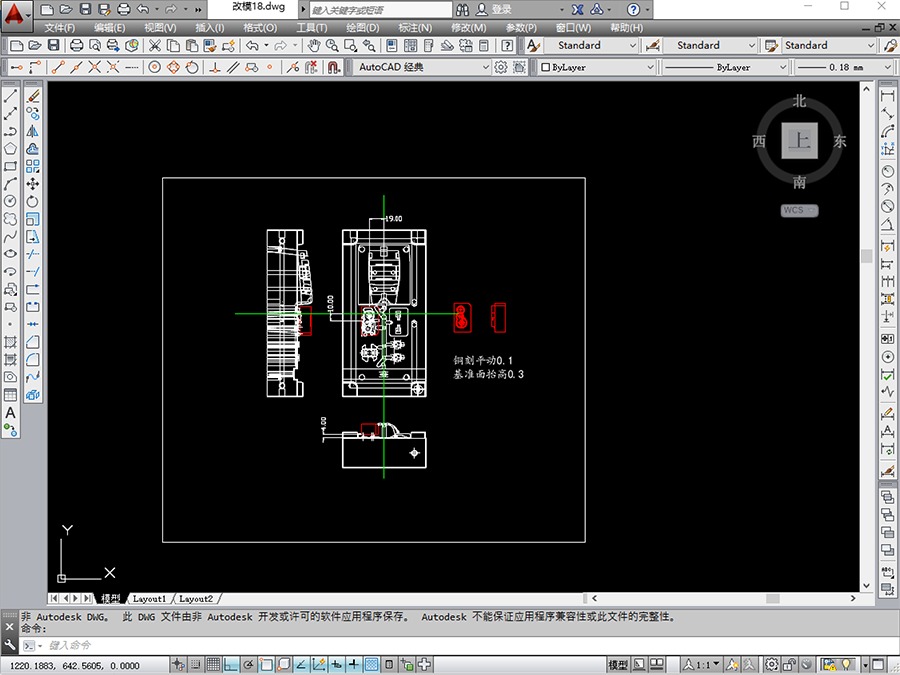

- Product Design & DFM Support (ODM)

- Custom Tooling and Mold Making

- Sample Manufacturing & Rapid Prototyping

- Mass Production (OEM)

- CNC Machining, Die Casting

- Injection Molding,Sheet Metal Fabrication

- Surface Finishing, Assembly & Packaging

- Global Logistics and Delivery

Why Choose Us for Contract Manufacturing?

From initial design support to mass production, assembly, and global delivery—we handle the entire process so you can focus on your core business.

Our in-house facilities cover 3D printing, die casting, injection molding, CNC machining, sheet metal fabrication and surface finishing for metal and plastic parts.

We are ISO 9001:2015 and IATF 16949 certified, ensuring consistent quality and compliance with RoHS and REACH standards.

Whether you need 100 prototypes or 1 million production units, our flexible capacity supports projects of any size.

By managing the full supply chain, we help you reduce operational costs and shorten your time-to-market.

We provide worldwide shipping with clear communication at every stage of your project.

Our Working Process – Contract Manufacturing

Initial Consultation & Project Assessment

We start by understanding your product requirements, timelines, and target markets. Our team assesses your project scope and offers tailored solutions.

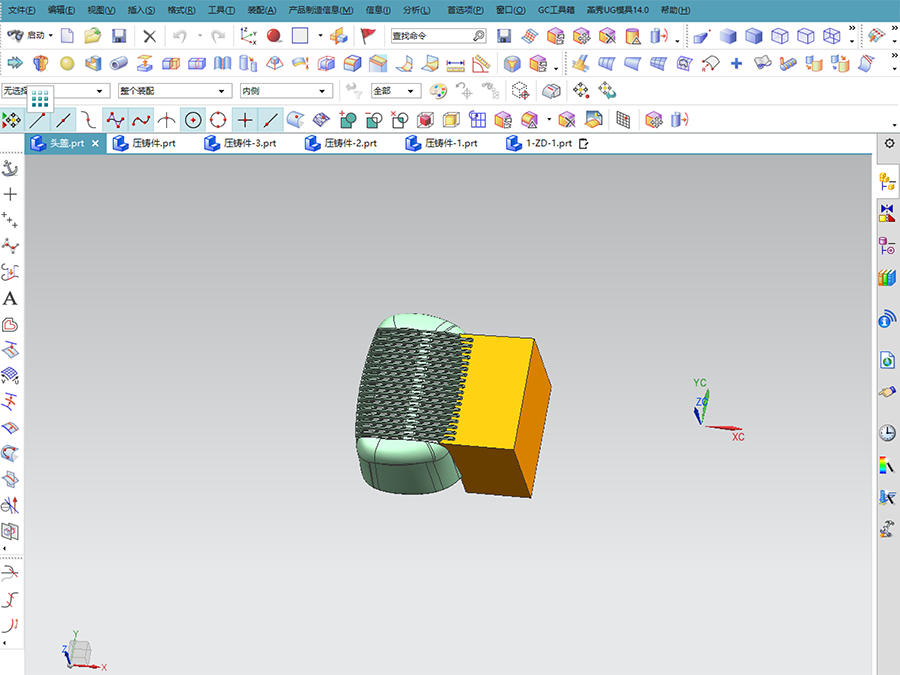

Design Support & Engineering (ODM Optional)

For ODM projects, we provide design for manufacturability (DFM) support, CAD modeling, and prototype development to refine your product before mass production.

Tooling & Sample Production

We develop custom molds, dies, and tooling. Sample production ensures your specifications are met and provides an opportunity for design adjustments.

Scalable Mass Production (OEM)

With advanced facilities covering die casting, injection molding, CNC machining, and assembly, we deliver high-volume production with consistent quality.

Quality Assurance & Compliance

Each stage includes rigorous QC inspections and compliance with ISO 9001:2015, IATF 16949, and RoHS/REACH standards.

Assembly, Packaging & Global Delivery

We handle final assembly, custom packaging, and worldwide shipping to ensure your products arrive on time and ready for market.

Focus on growing your business – we’ll take care of production.

OEM ODM solutions tailored to your needs.

Explore materials. Explore possibilities. Start your journey with us.

Applications in Multiple Industries

Empowering your success with advanced, high-quality solutions for every industry

Recent Blog Posts

需要添加几篇文章这里再引用