Custom Die Casting Services

High-Precision Metal Casting for Complex Parts — Zinc & Aluminum Solutions Under One Roof

- Certifications ISO 9001:2015 | IATF 16949

What Is Die Casting?

Die casting is a manufacturing process that injects molten metal into steel molds to create precise, high-strength parts.

How Does Die Casting Work?

Molten zinc or aluminum is forced into a metal die under high pressure, rapidly forming complex shapes with tight tolerances.

Key advantages:

Die casting offers excellent dimensional accuracy, fast production rates, and superior surface finishes for metal components.

Our Die Casting Capabilities

Up to 400T hot chamber (Zinc)/ 800T cold chamber (Aluminum)

±0.01 mm with post-machining

Prototype to High-Volume Manufacturing

ISO 9001:2015 & IATF 16949 certified, with CMM inspection & SPC monitoring

Explore Our Specialized Die Casting Services

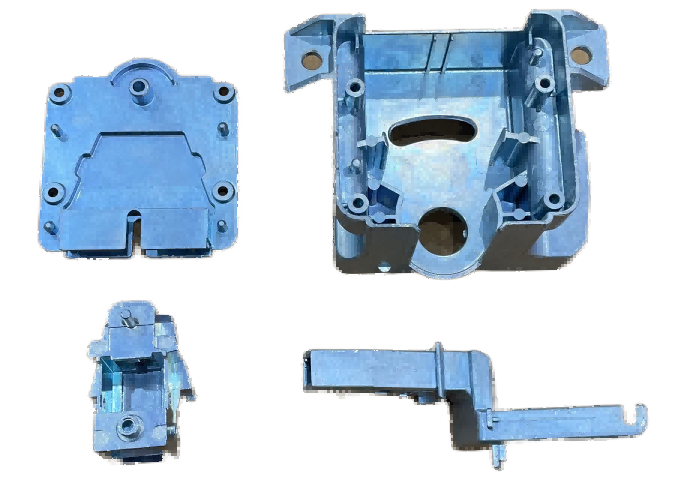

Zinc Die Casting Services »

Zamak 3 & Zamak 5-based solutions for small to medium parts with complex shapes and excellent corrosion resistance.

→ Ideal for: Automotive interiors, smart lock housings, home hardware.

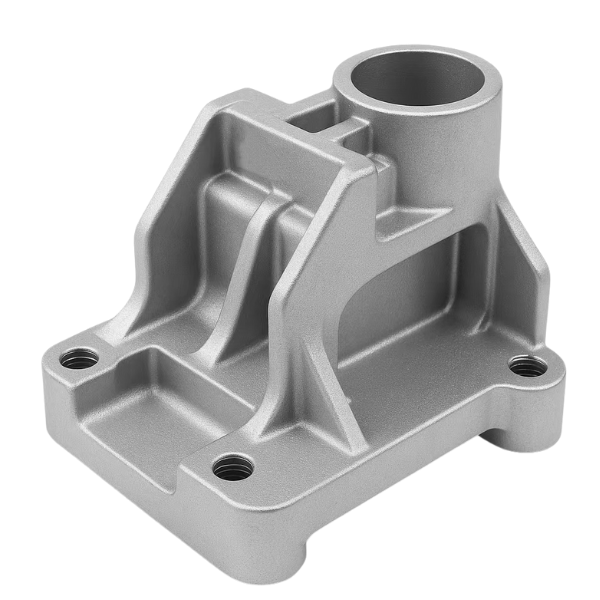

Aluminum Die Casting Services »

Aluminum alloy die casting for high-strength, lightweight components with excellent thermal and mechanical properties.

→ Ideal for: Engine blocks, electronic housings, suspension components.

Why Choose Us

20+ years of manufacturing experience

Advanced machines & strict quality control

ISO 9001 & IATF 16949

Design to finished product

Compliant with RoHS & REACH

Dedicated project tracking and global delivery

Surface Finishing Options

Applications in Multiple Industries

Empowering your success with advanced, high-quality solutions for every industry.