Vacuum Casting

Delivering precise prototypes and small batches with German vacuum systems and automated production lines.

- Certifications ISO 9001:2015 | IATF 16949

What is Vacuum casting?

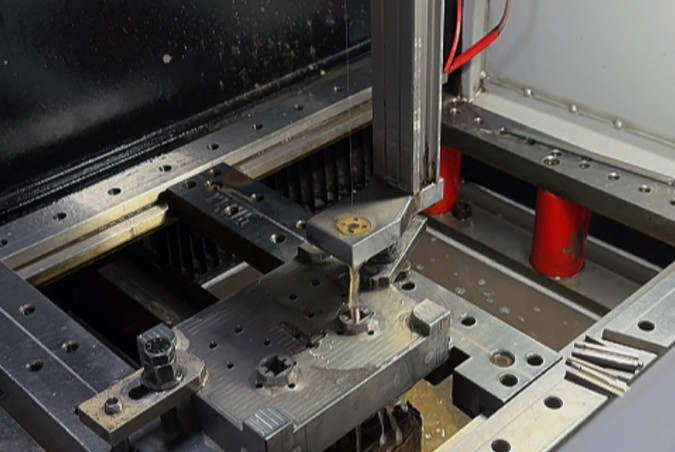

Vacuum casting is a rapid manufacturing process that uses silicone molds and polyurethane resins to produce high-quality prototypes and small batches.

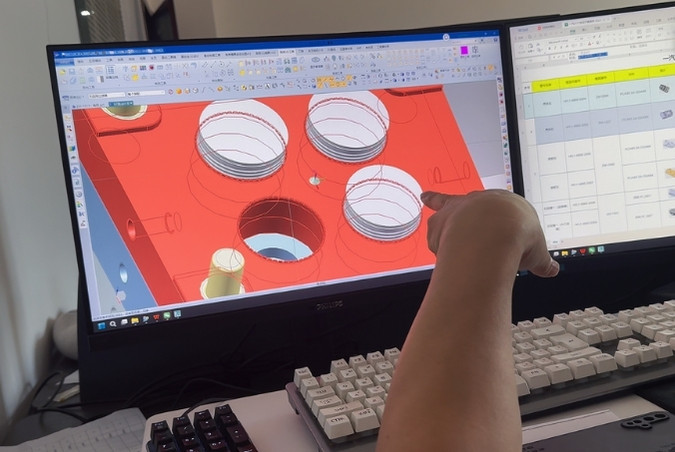

How it works?

The process involves pouring resin into a silicone mold under vacuum to replicate the master model with precise details and bubble-free finishes.

Key advantages:

Fast turnaround, cost-effective, excellent surface quality, and material versatility.

Our Aluminum Die Casting Services & Capabilities

- In-House Developed Automated

- Lines: 4 fully automated vacuum casting lines designed for efficiency and precision.

- German Vacuum Systems: Bubble-free casting with superior surface finishes and fine feature replication.

- Custom mold solutions for complex parts and high volumes

- 20+ years of engineering expertise

- Full DFM analysis to ensure cost-effective, high-quality production

- Mold Life: Up to 20 casts per silicone mold

- Batch Size: Ideal for 1–50 parts

- Lead Time: Prototypes delivered in as little as 3–10 days

- ISO 9001:2015 & IATF 16949 certified

- SPC monitoring and CMM inspections for consistent precision

Material Options for Vacuum Casting

We offer a variety of polyurethane resins that simulate production-grade plastics:

ABS-like: Tough and impact-resistant for functional parts.

PMMA-like: Crystal-clear finish for optical components.

PP-like: Flexible and durable for real-world testing.

High-temp resins: Designed for heat-resistant applications.

Perfect for prototypes and low-volume production with excellent surface quality.

Applications of Vacuum Casting

Our vacuum casting services support a wide range of industries and applications:

- Automotive

- Consumer Electronics

- New Energy & Industrial Applications

- Home Appliances

Looking for a trusted partner for your vacuum casting project?

Why Choose Us

20+ years of manufacturing experience

Advanced machines & strict quality control

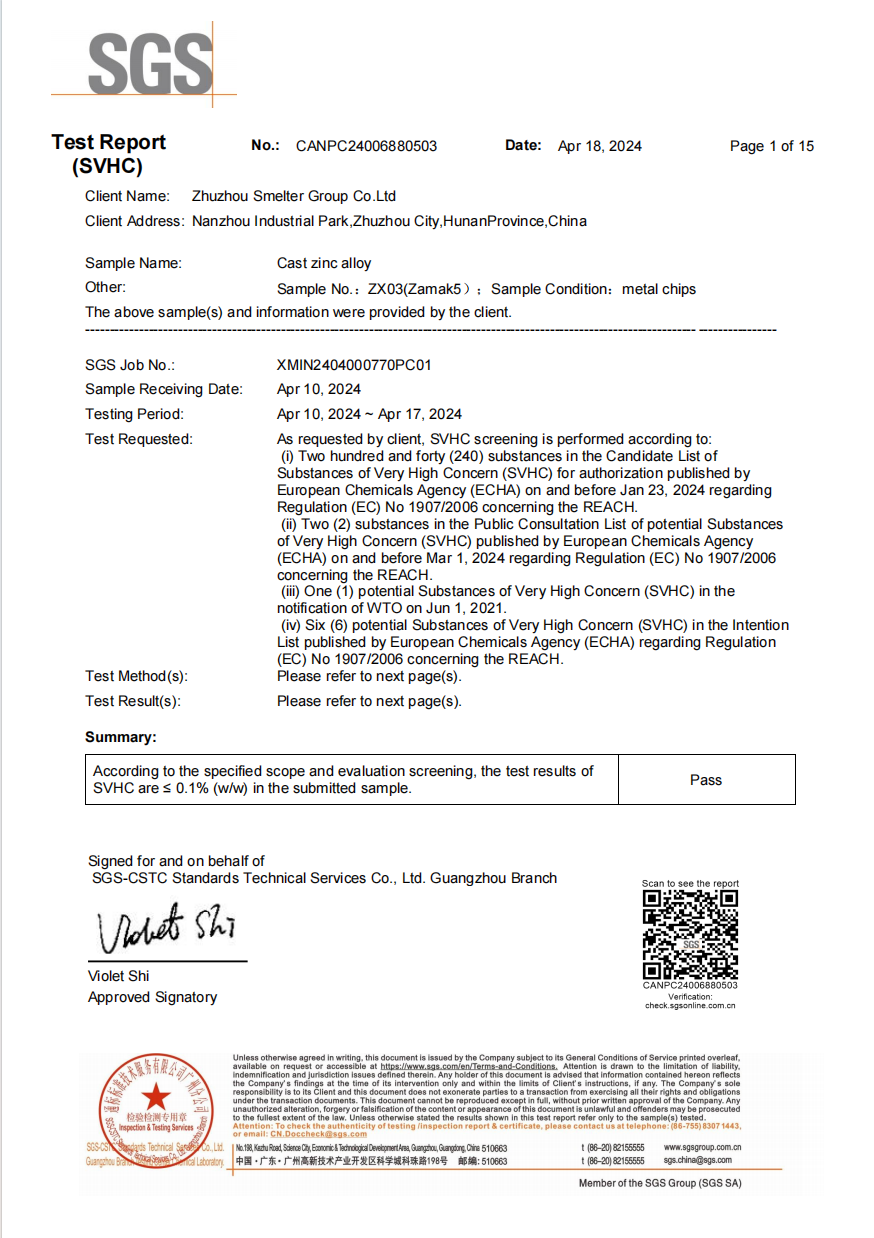

ISO 9001 & IATF 16949

Design to finished product

Compliant with RoHS & REACH

Dedicated project tracking and global delivery

FAQ – Frequently Asked Questions

Q: Can vacuum cast parts be painted or finished?

A: Yes, we offer a variety of surface finishes including painting, texture coating, and color matching to meet aesthetic and functional needs.

Q: How long does a typical silicone mold last?

A: Each silicone mold can produce up to 20 high-quality parts before it needs to be replaced.

Q: Is vacuum casting suitable for functional testing?

A: Absolutely. With material options like ABS-like and high-temperature resins, our parts are ideal for functional and performance testing.

Q: Do you support international shipping?

A: Yes, we deliver vacuum cast parts globally with full logistics support.

Recent Blog Posts

需要添加几篇文章这里再引用