Metal 3D Printing Services for Rapid Prototyping

Accelerate Product Development with Industrial-Grade Accuracy

— From Prototype to Production

— Powered by Metal Additive Manufacturing

What is Selective laser sintering (DMLS) ?

Direct Metal Laser Sintering (DMLS) is an advanced industrial metal 3D printing technology that produces fully functional prototypes and production-quality parts in as little as 7 days. Leveraging a wide selection of metal alloys—including stainless steel, titanium, and Inconel—DMLS delivers high-strength components with complex geometries, ideal for end-use applications in aerospace, automotive, medical, and other high-performance industries.

How does DMLS 3D Printing work

DMLS works by spreading thin layers of metal powder and using a high-powered laser to selectively sinter each layer based on a 3D model, building the part layer by layer, followed by controlled cooling and post-processing to achieve final functional properties.

Key advantages

DMLS Advantages: DMLS enables the production of fully dense, high-precision metal parts with complex geometries, without tooling, making it ideal for rapid prototyping and low-volume end-use applications across demanding industries.

Applications of DMLS

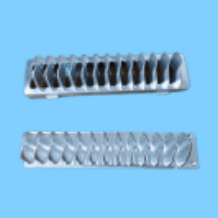

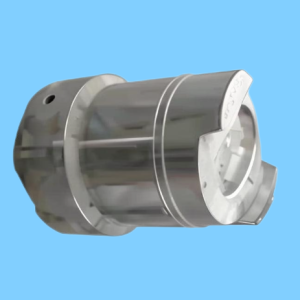

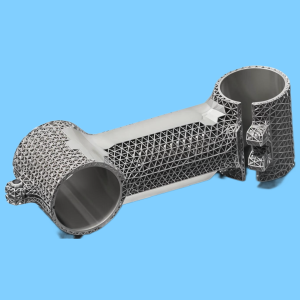

DMLS is widely used to produce high-strength, complex metal parts for aerospace, automotive, medical, tooling, and industrial applications

- Aerospace: Turbine blades, brackets, lightweight structural parts

- Automotive: Intake manifolds, heat exchangers, custom brackets

- Medical: Orthopedic implants, dental frameworks

- Tooling: Mold inserts with conformal cooling, production tools

- Electronics: Heat sinks, RF and microwave components

3D Printing Spec

Get this quick reference to learn about materials, finishes, considerations and technology options for our 3D printing technologies.3D Printing.xlsx

Our Capabilities with Metal 3D Printing

Supports a variety of metal powders including

- Stainless Steel (316L, 17-4PH)

- Titanium (Ti6Al4V)

- Aluminum (AlSi10Mg)

- Inconel (625, 718)

- Cobalt-Chrome

Capable of achieving ±0.1 mm tolerances, suitable for functional prototypes and end-use parts in demanding industries.

Accommodates small, detailed components and larger assemblies with build volumes up to 250 x 250 x 300 mm (or customized based on system).

We offer heat treatment, CNC finishing, support removal, polishing, and surface coating, delivering parts ready for real-world use.

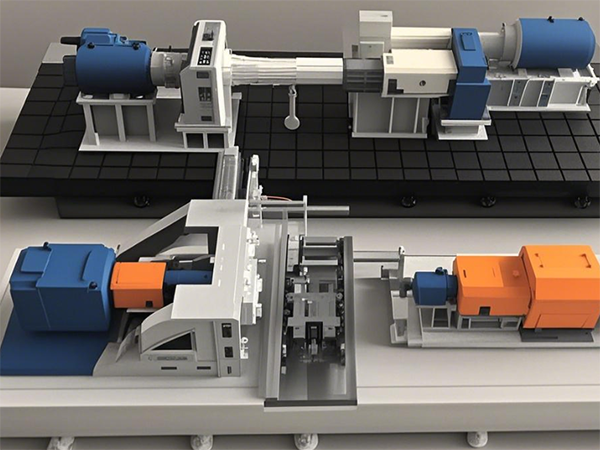

Exhibition Snapshot - Shared with Client's Approval (3D Printing)

Our 3D printing has helped clients cut design iteration time by up to 50%, enabling faster product launches and timely trade show presentations.

Printable Materials for DMLS 3D Printing

| Material | 316L Stainless Steel | 1.2709 Maraging Steel (Aged) | AlSi10Mg Aluminum Alloy | Ti6Al4V Titanium Alloy | Nickel-based Alloy IN718 (+HIP) |

| Picture |  |  |  |  |  |

| Operating Temperature | < 500°C | 400°C (Max 500°C) | < 150°C | 350°C | -253°C ~ 700°C |

| Minimum Wall Thickness | 0.2–0.3 mm | 0.3–0.4 mm | 0.3–0.4 mm | 0.3–0.4 mm | 0.3–0.4 mm |

| Surface Roughness (30μm layer thickness) | Ra 6μm Rz 15μm | Ra ≈ 7 μm | Ra 10μm Rz 30μm | Ra 6μm Rz 20μm | Ra ≈ 6–10 μm |

| Surface Roughness (60μm layer thickness) | Ra 10μm Rz 35μm | Ra ≈ 10 μm | Ra 15μm Rz 35μm | Ra 8–12μm Rz30–35 μm | Ra ≈ 8–15μm |

| Tensile Strength (horizontal direction) | 600 ± 20 MPa | ≈ 1950 MPa | 430 ± 20 MPa | 950 MPa | ≈ 1490 MPa |

| Yield Strength | 500 ± 10 MPa | ≈ 1900 MPa | 245 ± 10 MPa | 860 MPa | ≈ 1240 MPa |

| Elastic Modulus | 180 ± 5 GPa | ≈ 190 GPa | 70 ± 5 GPa | 116 GPa | ≈ 200 GPa |

| Elongation | ≈ 30 ± 2 % | ≈ 4 % | ≈ 9 ± 2 % | ≈ 10% | ≈ 13% |

| Hardness | 250 ± 5 HV | ≈ 52 HRC | 120 ± 5 HV | 320 HV | ≈ 460 HV |

Why Choose Us

20+ years of manufacturing experience

Advanced machines & strict quality control

ISO 9001 & IATF 16949

Design to finished product

Compliant with RoHS & REACH

Dedicated project tracking and global delivery

Important Notes for 3D Printing

Minimum Wall Thickness:

- Recommended minimum wall thickness for plastic/resin parts: ≥ 0.8 mm;

- Recommended minimum wall thickness for metal parts (SLM): ≥ 0.3–0.5 mm;

- Walls thinner than recommended might fail during printing or deform easily. Please confirm in advance.

To ensure smooth processing for mold design and manufacturing, please kindly follow these guidelines when exporting and submitting STL files:

- Triangle Face Normals

Please make sure that the normals of all triangle faces are correctly oriented — the front and back faces should not be reversed. All face normals should point outward to define a closed, solid model. Incorrect normals may cause errors in printing or mold analysis. - No Holes or Gaps

The STL file must represent a watertight, fully closed solid. There should be no missing faces or holes in the geometry. Non-manifold edges or open surfaces may result in processing or printing failures.

If possible, please run a mesh check or repair in your modeling software before exporting the STL file.

Dimensional Accuracy and Tolerances:

- Our standard tolerance ranges are:

Resin (SLA/DLP): ±0.05–0.1 mm;

Nylon (SLS): ±0.1–0.2 mm;

Metal (SLM): ±0.1–0.2 mm;

CNC Machined Parts: ±0.1 mm - If higher precision or special tolerances are required, please clearly specify in advance.

Assembly Requirements:

- For parts requiring assembly, please provide clear assembly drawings and instructions. We will assemble and inspect the parts before shipment.

- If no assembly request or assembly drawings are provided by the customer, we will not assemble by default and will not be responsible for any resulting issues.

- Recommended assembly clearance: at least 0.15 mm per side.

Painting Color Standards:

- If painting is required, please provide a clear Pantone color code or standard color sample.

- If no color code or sample is provided, we will not be responsible for any color deviation.

Special Requirements for CNC Machined Parts:

- For CNC machined parts, please provide 2D engineering drawings clearly indicating tolerances, thread specifications, and any special machining requirements.

- Without provided 2D drawings, we will manufacture according to the supplied 3D data and standard international tolerances. Areas without special instructions will be processed according to general standards.

Additional Recommendations (For Reference):

- Small threads are recommended to be machined or inserted separately; direct 3D printing of small threads is generally not advised.

- Please inform us in advance regarding specific mechanical requirements (strength, toughness, heat resistance, etc.) to confirm suitable materials and processes.

- Long, thin, unsupported, or thin-walled structures may deform; structural optimization during the design stage is highly recommended.