High-Precision 3D Printing Services

Trusted by manufacturers for low-volume production and rapid prototyping

- Certifications ISO 9001:2015 | IATF 16949

What is 3D Printing

3D printing is an additive manufacturing process that creates three-dimensional parts layer by layer from digital CAD models.

How It Works?

A 3D printer builds the part by depositing or solidifying material—typically plastic or metal—according to the design’s exact specifications.

3D Printing Services for Industrial Applications

Unlock design freedom and accelerate product development with our advanced 3D printing services. We offer end-to-end additive manufacturing solutions tailored for functional prototyping, complex geometries, and low-volume production of end-use parts.

SLA

(Stereolithography)

Smooth, high-detail plastic prints for visual models and prototypes.

SLS

(Selective Laser Sintering)

Durable, support-free plastic parts with complex geometries.

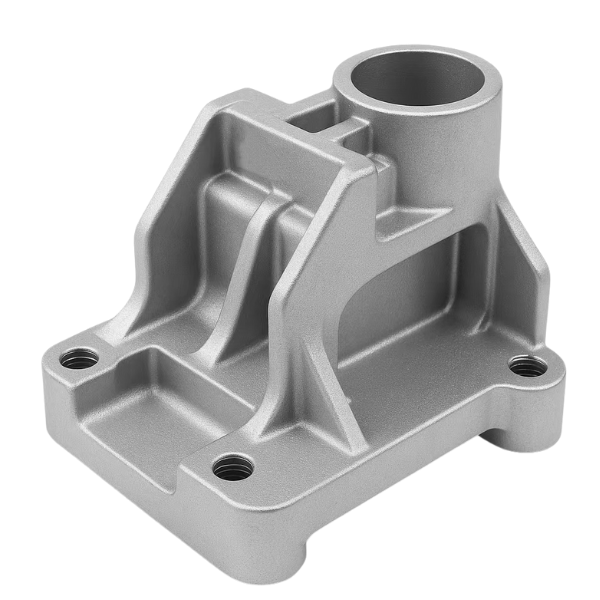

DMLS

(Direct Metal Laser Sintering)

Functional metal components for industrial-grade applications.

Why Choose 3D Printing?

3D printing shortens design-to-production cycles, enabling rapid prototyping and quicker time-to-market.

It reduces tooling, labor, and material costs—ideal for validating designs before full-scale production.

Create intricate part geometries and internal features that are difficult or impossible with traditional methods.

Eliminates the need for molds or fixtures, saving upfront investment and speeding up early-stage development.

Whether you need one prototype or a short-run batch, 3D printing offers unmatched scalability.

Supports both plastic and metal materials to meet functional, cosmetic, and mechanical requirements.

Choosing the Right 3D Printing Process

Process | Best For | Materials | Key Benefits | Tolerance | Delivery Time |

Small, detailed parts and visual prototypes | UV-sensitive resins, similar to ABS | High precision, smooth finishes | High accuracy for small parts | 1-3 days | |

Durable, functional parts with complex geometries | Nylon, glass-filled nylon, metal alloys | No support structures, excellent strength and heat resistance | ±0.1-2.5 mm | 2-4 days | |

Metal parts for functional use, tooling inserts, aerospace | Stainless steel, aluminum, titanium, mold steel | Strong, fully functional metal parts | High precision in metal parts | 4-7 days |

is right for your project?

Our Capabilities with 3D Printing

We offer SLA, SLS, and DMLS to suit different materials and part requirements.

Choose from resins, nylons, and metals like aluminum, stainless steel, and titanium.

We produce parts with tight tolerances and complex geometries, including internal features.

Standard lead times range from 1 to 7 days, depending on the process.

Ideal for single prototypes or low-volume production—no tooling required.

We offer painting, polishing, plating, anodizing, and more for functional or cosmetic finishes.

3D Printing Spec

Get this quick reference to learn about materials, finishes, considerations and technology options for our 3D printing technologies.

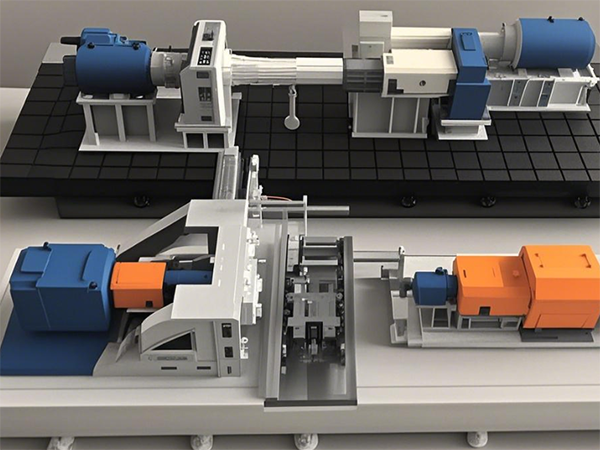

Exhibition Snapshot - Shared with Client's Approval (3D Printing)

Our 3D printing has helped clients cut design iteration time by up to 50%, enabling faster product launches and timely trade show presentations.

Why Choose Us

20+ years of manufacturing experience

Advanced machines & strict quality control

ISO 9001 & IATF 16949

Design to finished product

Compliant with RoHS & REACH

Dedicated project tracking and global delivery

Surface Finish Options fo 3D Printing

To meet your functional and aesthetic needs, we offer a wide range of post-processing services for plastic and metal parts:

Decoration

Painting, silk screening, hot stamping, soft-touch coating

Polishing, sandblasting, brushing, leather texturing, transfer printing

Electroplating, anodizing, UV coating , overmolding

Laser engraving, pad printing

Our finishing services ensure your parts not only function perfectly—but look and feel just right for your market.

Important Notes for 3D Printing

Minimum Wall Thickness:

- Recommended minimum wall thickness for plastic/resin parts: ≥ 0.8 mm;

- Recommended minimum wall thickness for metal parts (SLM): ≥ 0.3–0.5 mm;

- Walls thinner than recommended might fail during printing or deform easily. Please confirm in advance.

To ensure smooth processing for mold design and manufacturing, please kindly follow these guidelines when exporting and submitting STL files:

- Triangle Face Normals

Please make sure that the normals of all triangle faces are correctly oriented — the front and back faces should not be reversed. All face normals should point outward to define a closed, solid model. Incorrect normals may cause errors in printing or mold analysis. - No Holes or Gaps

The STL file must represent a watertight, fully closed solid. There should be no missing faces or holes in the geometry. Non-manifold edges or open surfaces may result in processing or printing failures.

If possible, please run a mesh check or repair in your modeling software before exporting the STL file.

Dimensional Accuracy and Tolerances:

- Our standard tolerance ranges are:

Resin (SLA/DLP): ±0.05–0.1 mm;

Nylon (SLS): ±0.1–0.2 mm;

Metal (SLM): ±0.1–0.2 mm;

CNC Machined Parts: ±0.1 mm - If higher precision or special tolerances are required, please clearly specify in advance.

Assembly Requirements:

- For parts requiring assembly, please provide clear assembly drawings and instructions. We will assemble and inspect the parts before shipment.

- If no assembly request or assembly drawings are provided by the customer, we will not assemble by default and will not be responsible for any resulting issues.

- Recommended assembly clearance: at least 0.15 mm per side.

Painting Color Standards:

- If painting is required, please provide a clear Pantone color code or standard color sample.

- If no color code or sample is provided, we will not be responsible for any color deviation.

Special Requirements for CNC Machined Parts:

- For CNC machined parts, please provide 2D engineering drawings clearly indicating tolerances, thread specifications, and any special machining requirements.

- Without provided 2D drawings, we will manufacture according to the supplied 3D data and standard international tolerances. Areas without special instructions will be processed according to general standards.

Additional Recommendations (For Reference):

- Small threads are recommended to be machined or inserted separately; direct 3D printing of small threads is generally not advised.

- Please inform us in advance regarding specific mechanical requirements (strength, toughness, heat resistance, etc.) to confirm suitable materials and processes.

- Long, thin, unsupported, or thin-walled structures may deform; structural optimization during the design stage is highly recommended.